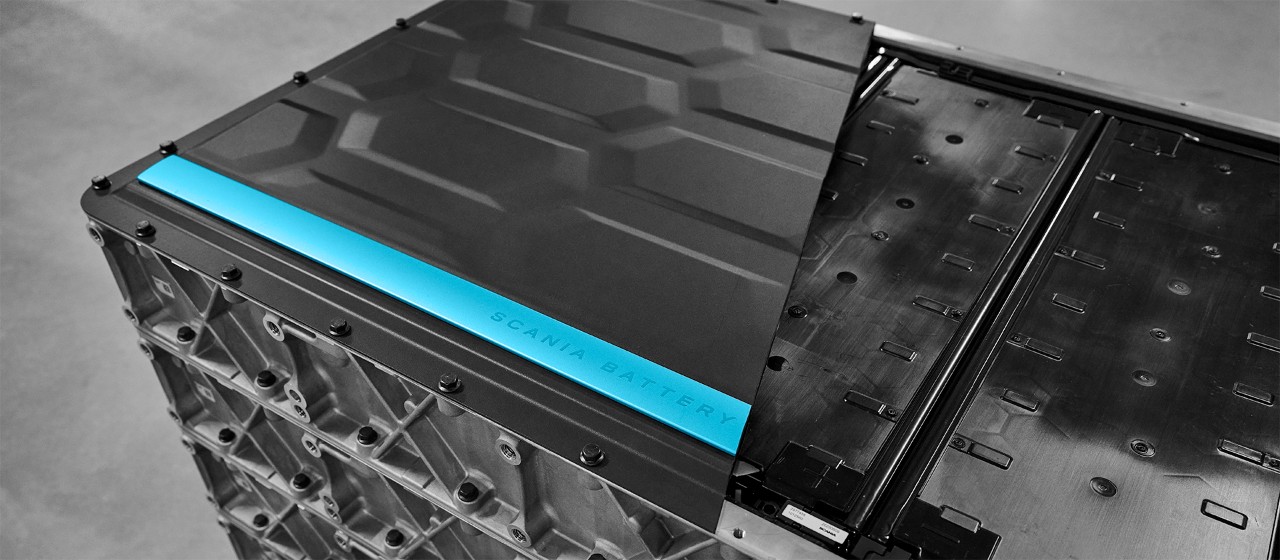

A closer look at Scania’s next-generation battery

The batteries inside a Scania electric vehicle combine the world’s greenest battery cells with battery packs and modules that have been developed for the energy and performance needs of heavy transport. Let’s take a closer look at what each battery contains.

When the first generation of heavy-duty electric vehicles emerged, the installed battery packs consisted of battery cells that were originally developed for passenger cars. However, Scania’s e-Mobility developers realised that this wouldn’t work in the long run because heavy transport has radically different demands on energy output, usage and charging.

So, a few years ago, a team within Scania’s Research & Development department began drafting ideas for how the next generation of batteries for heavy duty transport should be designed.

“Together with our partner Northvolt, we had the opportunity to start from a clean sheet to develop the optimum battery cell for heavy-duty vehicles,” says Viktor Regefalk, Product Owner for battery packs at Scania.

BEV batteries.

“We receive the cells from Northvolt and assemble the cells into modules. Then we put the modules into packs and integrate the software that we’ve developed here at Scania. Scania is unique in the extent to which we do all of this hardware and software work ourselves. This gives us the advantage of having complete control of battery development, meaning we can customise our battery-electric vehicle offer for each individual customer’s needs.”

So, what do these next-generation batteries look like and how will they make a difference to our customers and the shift to sustainable transport?

- The world’s most sustainable battery cells. Together with our partner Northvolt, we always give great consideration to the recyclability of the batteries, with their circularity in constant focus. There are significant reductions in CO2 emissions from our battery production, and emissions will be cut further in the future through improvements in electricity that’s produced from renewable sources. We’re working hand-in-glove with Northvolt to ensure there is a sustainable value chain for the whole of our battery partnership.

- Developed and tailor-made for heavy-duty transport. The use-case analyses that we have carried out with our customers have given us deep insights into how they have been using their vehicles. This has enabled us to tailor the batteries to meet the demanding requirements of heavy-duty transport, including battery lifetime, range, charging and power output. In particular, our batteries are designed to be charged, used and re-charged over a total lifespan of 1.5 million kilometres.

- Modular. With the introduction of Scania’s new modular battery platform we can take into account different customer applications. This way, the customer’s battery-electric vehicle can be tailored according to their individual demands regarding aspects such as vehicle configuration, range and power.

- Safety. Safety is the uppermost consideration in all aspects of our battery development and verification, including mitigating against thermal safety, electrical safety and vehicle accident risks. We continue to carry out extensive testing of our batteries to ensure the product meets Scania and the industry’s rigorous product safety requirements.

- Future-proof charging. Our batteries are capable of accepting 375kW charging power: the highest possible rate presently available on the market. We have also prepared our batteries for the upcoming ultra-fast Megawatt Charging System (MCS). Our cells, modules, packs and cables are specified for higher currents to meet customer charging needs. Because our batteries are developed in-house, we can ensure that the batteries always charge at the right temperature, according to customers’ individual needs. This enables reduced charging time and prolongs the life of the battery.

BEV batteries – key facts

- Battery cell: Basic unit of a lithium-ion battery that exerts electric energy by charging and discharging. Made by inserting cathode, anode, separator and electrolyte into a rectangular aluminium case. Scania’s battery cells are produced by Northvolt, a Swedish company that aims to produce the world’s greenest, most sustainable batteries, made with materials which to a large extent are derived from recycled batteries.

- Battery module: Each individual battery cell is assembled into a larger frame containing multiple battery cells, which are called a battery module.

- Battery pack: Composed of modules, a cooling system and a battery management system that oversees both battery control and protection systems. Typically, each vehicle has 4-6 battery packs, optimised for the customer’s vehicle and its intended operation.

Scania batteries – key facts

- In line with Scania’s circular business approach, the company has adopted a circular battery strategy which means that the company’s batteries could be reused, repurposed and recycled.

- The battery cells in Scania’s trucks are manufactured by Northvolt, a Swedish company that aims to produce the world’s greenest batteries made with materials derived from recycled batteries.

- Scania and Northvolt have developed a lithium-ion battery cell with the capacity to power trucks for 1.5 million kilometres – equivalent to the truck's whole lifetime.

- The battery cells are assembled in modules which are put into packs that are tailored for Scania’s modular production.

- As of September 2023, the battery modules and packs are assembled at Scania’s new battery assembly plant in Södertälje, Sweden.

Read more

Charging

We help you find the right charging solution for your specific need.