Inside Scania’s Super 13-litre powertrain – 8 percent fuel savings through engine-to-axle efficiency

22 JANUARY 2026

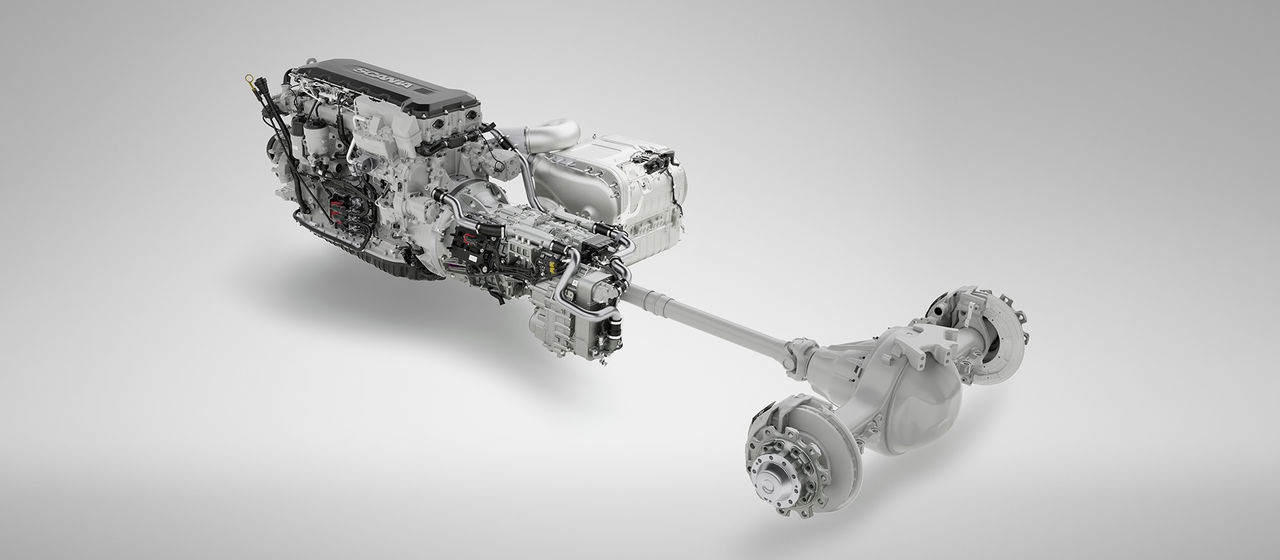

Huge leaps in fuel economy, serviceability and performance are delivered through Scania’s Super 13-litre powertrain for coaches. By rethinking how every component – from engine to axle – works together, Scania has achieved fuel savings of up to eight percent, creating a more sustainable, cost-effective and future-ready combustion powertrain. Our experts explain how.

Why integrated engine-to-axle efficiency is key to Scania’s 8 percent fuel savings

Prefer a quick overview? Watch the short videos below, where our experts summarise the key elements of the Super 13-litre powertrain. Use the arrows to see all three videos.

The main headline for Scania’s Super 13-litre powertrain for coaches is the eight percent fuel savings. That will make a huge difference to customer’s bottom lines and to overall sustainability in markets where electrification is limited or not yet possible.

However, this impressive feat wouldn’t be possible without a chain of updated components. The new Super powertrain represents a complete rethink of how every system – from engine to axle – works in harmony to deliver greater efficiency, longer lifespan and readiness for future emission and noise regulations, including Euro 7.

“We’ve improved the engine, aftertreatment, gear box, rear axle and our integrated control system. It’s not only the engine, but also the sum of these parts, combined with smart software and calibration, that delivers the gains,” says Niklas Berglund, Expert Engineer in Bus Chassis Development at Scania.

Niklas Berglund, Expert Engineer in Bus Chassis Development at Scania.

Add to that even greater reliability to maximise uptime, and it’s clear the Super powertrain will be a key bridging technology for many years to come.

Let’s find out where and how these efficiencies were made:

Transmission and rear-axle innovations

The new transmission alone contributes at least one percent additional fuel savings and features higher torque capacity, lighter weight and quicker gear shifting.

“It’s been one of the largest heavy duty transmission projects by predicted sales volume in the world. With this potential impact in mind Scania has gone the extra mile to make big improvements, including lighter weight and greater strength,” says Simulation Engineer, Jonas Larsson.

“By removing synchronisers and optimising the cog interaction, we’ve made gear shifts faster and more precise,” explains Niklas Berglund.

“We’ve also introduced a dry sump for the transmission, plus there has been a continuous evolution of bearings and the interaction between cogs, resulting in greater efficiency and reduced fuel consumption. This faster gear shifting in combination with the much higher total ratio of the transmission makes it easier to control the operation of the engine’s revs per minute (RPM). You can narrow down the engine speed to achieve the right engine load and speed for better fuel efficiency.”

Meanwhile, an updated rear axle allows lower engine speeds at the same vehicle speed, helping to cut fuel consumption further.

“The faster rear axles enable a lower speed of the transmission as well as the engine which lowers the losses and makes it possible to run the engine at its best operating point,” says Larsson.

New ‘FOU tank’ increases payload

FOU stands for fuel optimisation unit. It’s a smaller secondary system that is integrated with the main fuel tank on the Scania Super 13-litre engine and acts as a buffer to increase usable fuel volume and improve engine performance.

The FOU functions as a ‘catch tank’. It prevents air from entering the high-pressure fuel system by holding enough fuel when the vehicle is driving on inclines or declines. This design allows for longer service intervals and improves startability in cold weather.

“Sucking up diesel in small 20-litre tank means we can raise the utility rates of the main diesel tanks,” says Niklas Berglund. “On steep gradients, the diesel moves and the tanks suck in air but even if your vehicle sucks air into the main diesel tanks you can add diesel to the engine from the FOU catch tank.”

“This system makes it possible to have as much as 10 percent higher utilisation rate in the main tanks. The fuel saving and utilisation rate means we’ve been able to reduce the overall size and weight of the tanks by almost a quarter on the previous bus chassis. For customers with main diesel of 500 to 600 litres, that’s roughly 150 litres or 150 kg less weight: space for two more passengers or less fuel burn.”

Much longer service life

Another significant improvement is the Super powertrain’s extended service life, which will be a boon to customers in a very competitive sector where some companies’ vehicles can do 300,000 km a year.

“The new powertrain increases the lifespan of engine by 25 percent compared with the current platform, from 1.6 million to 2 million kilometres,” says Nicklas Sandberg, Product Manager at Scania People Transport with responsibility for Travel, Americas.

Nicklas Sandberg, Product Manager at Scania People Transport with responsibility for Travel, Americas.

Here, Scania’s modular system comes to the fore. The Super Powertrain shares some 90 percent of its components with the 13-litre engine that has been used on trucks since 2021, meaning they have been proved to be robust and reliable in the most challenging conditions, such as the depths of Nordic winter or high-altitude roads in South America.

“Having longer-lasting components requires fewer replacements, thus lower environmental impact,” Sandberg explains. “The shared parts also mean there is excellent global availability, reducing costs for the dealers who don’t have to stock more specialised parts, and for customers, who can find replacements quickly.”

Sandberg adds that the relocation of the oil filter to the cold side allows for faster maintenance because crews don’t have to wait so long for it to be cool enough to service. “That all adds up across a large fleet,” he says.

“Robust and ready for what’s next”

Having been extensively validated through the EU’s VECTO simulation tool for CO₂ emissions and fuel consumption, as well as open-road testing, the Super Powertrain is ready for Euro 7 and compatible with all biofuels.

“In many global markets, such as South America, there isn’t the same progress towards electrification that we see in Europe. We are still dependent on combustion engine vehicles, so that 8 percent improvement in fuel efficiency also means lowering the CO₂ footprint by 8 percent,” says Sundeep Kumar, Head of Travel Solutions at Scania People Transport.

Sundeep Kumar, Head of Travel Solutions at Scania People Transport.

“We needed to have a completely new platform that could future-proof our travel sector customers to be able to meet the current and coming regulatory demands for the next ten years or so. Now we’ve done that.”