Old Scania workwear finds new life in truck panels

9 JUNE 2025

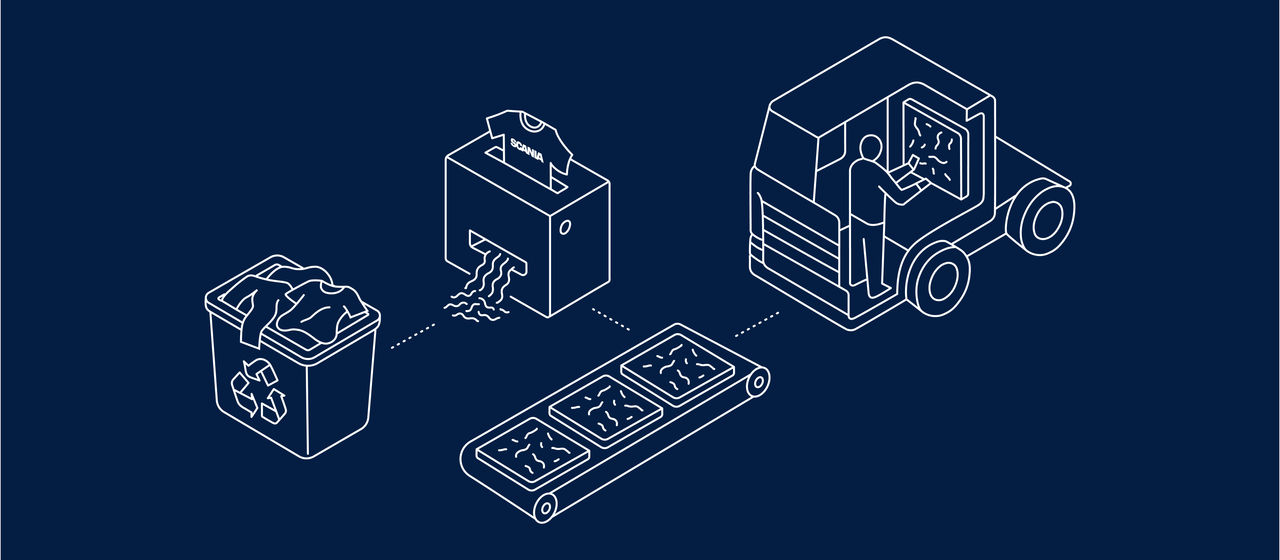

An imaginative new circular business initiative is bringing new purpose to old Scania workwear. It originated with Scania Latin America in Brazil, and has now expanded to Europe.

It’s no secret that Scania is embracing circularity. You’re probably already aware of Scania’s fantastic remanufactured gearbox project. Or perhaps you read about the clever idea of sand from our foundry being reused by Weber St-Gobain for making their floor putty filler. Maybe you even own a piece from the Scania workwear range that blends cotton with recycled materials including coffee grounds, to make premium clothes.

But have you heard the story about how old production workwear from Scania is now being recycled into the soft material that is used for the inner panels in our truck cabs?

“Instead of burning used clothes or letting them go to waste, we saw an opportunity to turn them into something new; and what could be better than integrating the material into our trucks?” says Jeanette Stigesjö, a Sourcing Manager within Scania Procurement who has been working with suppliers on sustainability since 2017.

Jeanette Stigesjö, Sourcing Manager at Scania.

How the initiative came about

The seed of this idea was actually planted back in 2018/19, when Scania was approached by its workwear supplier, Fristads, to find out whether it would be interested in a sustainability project.

This led to the Sustainable Workwear Collection, ethically-made garments that came with an official Environmental Product Declaration (EPD). The collection was a real hit with our customers and Scania fans, and opened the way to developing the idea of recycled and repurposed clothing even further.

The next inspiration came in 2022, when Scania Latin America took its first steps in textile recycling for use in the production of phenolic felt that is used for the inner panels of cabs. Jeanette’s colleague Heléne Rosengren, an environmental specialist within the Group Environment team, heard about the SLA initiative at a meeting on Scania circular business initiatives in March 2022. Heléne felt it could be expanded into Europe.

“Heléne and I spoke to R&D regarding whether the material met the right specifications in terms of safety and quality standards that our supplier could use for the inner lining,” says Jeanette. “It’s a mix of cotton and polyester. The workwear is also made from cotton and polyester, which gives them the right quality for being used.”

The duo then asked Vanya Trivkovic, who has responsibility for inner panels for the trucks, whether something could be done with the workwear, and recycle it for the inner cab linings.

Late last year, a full-scale recycling initiative was launched. Scania’s laundry specialist Elis Textilservice cleaned the old workwear. From there it was sent to Altex, a textile recycling specialist based in Germany, which then rendered the t-shirts and other clothes into fibres.

These fibres were then sent to Autoneum, Scania’s vehicle interior supplier, which used them as the basis of the soft inner linings they manufacture for truck the cabs. These linings don’t just have an aesthetic appeal-they also help to dampen the sound in the cab, improving driver comfort.

“We started with approximately 1,600 panels in late 2024, each made from about 27kg of recycled material,” says Jeanette. “The panels are now fitted in the cabs of Scania trucks that are out on our roads.” Jeanette adds that there is a lot more to come.

Once worn out, pullovers like the one depicted, can be recycled into soft material for the inner panels of our truck cabs.

Saving water, cutting carbon emissions

The results of these initiatives speak for themselves. Recycling workwear instead of disposing of it saves the equivalent of 2,104,673 m3 of water per year, while cutting CO₂ emissions by the equivalent of 545 return flights from Stockholm to Paris.

“These are real, measurable savings,” Jeanette says. “We’re the first large company in the world with EPD-declared garments. When all clothes are environmentally declared it means that the entire production chain and lifecycle is reviewed because the EPD is a third-party verified document that details the environmental impact of a product during its life cycle, from construction and material choices to waste and transports. Switching to the new environmentally declared garments will save so much CO₂ and water over its lifetime compared with a conventionally produced collection. This is a certification that allows us to track the CO₂ and water footprint for each individual garment and that transparency is key to pushing sustainability forward.”

Jeanette is also keen to emphasise that this was also very much a team effort involving several areas of the Scania business.

“This latest project with the inner panels is a fantastic example of how cross-functional cooperation can drive real change,” she says.

“We had people from Global Health, Safety and Environment, Procurement and R&D working together, along with our suppliers, to make this happen. It’s a huge step towards integrating circularity into our production processes.”

Recycling by the numbers: Water, Carbon, and Circularity Impact

- Each year, Scania’s recycling initiative saves 2,104,673 m³ of water.

- The program reduces CO₂ emissions by an amount equivalent to 545 round-trip flights between Stockholm and Paris.

- Every inner panel is made from approximately 27 kg of recycled cotton and polyester sourced from old workwear.

- Since late 2024, 1,600 of these recycled panels have been manufactured and fitted into Scania truck cabs currently on the road.

A model for the future

Looking ahead, Scania is exploring ways to expand the clothing project even further. With a shift towards generic-sized uniforms to improve availability and reduce overall waste, the company is also tracking laundry cycles using transponders embedded in t-shirts.

“The goal is to reduce how many new garments we need in the first place,” Jeanette Stigesjö explains. “And when uniforms do reach the end of their life, we want to ensure they can be reused again in this circular loop.

“We’ve shown that sustainability and efficiency can go hand in hand. The challenge now is to scale this up and inspire others in the industry to do the same.”

By transforming old workwear into truck components, Scania isn’t just reducing waste – it’s reimagining the future of materials. And in doing so, it’s proving that sustainability isn’t just about what we throw away, but what we choose to create.