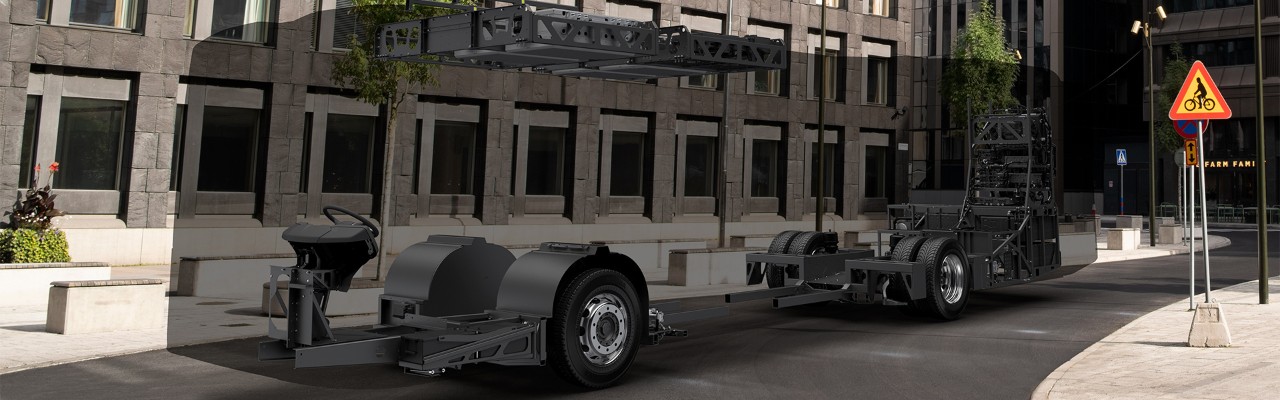

Scania C-chassis Low floor

Powertrains

The low floor Scania C-chassis offer a wide range of energy efficient and reliable powertrains optimised for inner-city traffic.

| Volume | Output | Torque | Emission control | Fuel options |

|---|---|---|---|---|

| 7-litre | 280 Hp (206 kW) | 1200 Nm | Selective catalytic reduction (SCR) | Biodiesel, HVO, Diesel |

| 9-litre | 320 Hp (235 kW) | 1600 Nm | Selective catalytic reduction (SCR) | Biodiesel, HVO, Diesel |

| Fuel capacity: 140 - 360 litres Gearbox: 6-speed fully automatic with acceleration control | ||||

| Volume | Output | Torque | Emission control | Fuel options |

|---|---|---|---|---|

| 9-litre | 280 Hp (206 kW) | 1350 Nm | Exhaust gas recirculation (EGR) | Biogas, natural gas |

| 9-litre | 340 Hp (250 kW) | 1600 Nm | Exhaust gas recirculation (EGR) | Biogas, natural gas |

| Fuel capacity: 1260-1875 litres Gearbox: 6-speed fully automatic with acceleration control | ||||

Axles

The low floor Scania C-chassis is available in several variants enabling it to meet different operational demands.

4x2 - independent suspension or rigid axle

6x2/2 - (artic) independent suspension or rigid axle

Floor level

The low entry point and flat floor throughout the bus increases accessibility for all passengers, including wheelchair users and children in strollers. In combination with the wide aisle, these features also contribute to efficient passenger flow.

Design features

The low floor Scania C-chassis meet the needs of operators on every continent. With total design and production control over chassis and powertrain, Scania delivers unrivalled reliability, durability and performance.

Passenger capacity

The chassis enable a technical capacity of up to 100 passengers. this is not least achieved through very high axle load capacity and reduced weight. The high passenger capacity figure can contribute to a more efficient public transport system and potentially keep costs down by minimising total vehicle fleet investments.

Front suspension technology

Without compromising on passenger capacity, the new independent front suspension offers excellent passenger comfort and enables a wider aisle (900 mm). This results in new layout possibilities, increased passenger flow, space and accessibility.

Driver area

Offers excellent ergonomics through all angle step-less seat adjustments, adjustable instrument panel, flexible switch placement . A lower instrument panel increases visibility. The buses have excellent drivability with a great turning radius, advanced driver assistance systems, and improved assisted handling, steering and braking. Also, they offer increased safety, a better climate system and good noise and vibration reduction.

Powertrain technology

The highly dependable, durable, and robust powertrains enable fuel savings of up to 21%, achieved through a number of factors such as; engine efficiency (-6%), changed driveline position (-3%), improved gearbox (-3%), weight reduction (-3%) and the addition of a start/stop function (-6%).

Continue to explore

Contact your dealer

Please contact us if you have any questions about our products, services or other activities within the Scania organisation.