Scania's Science based targets

Scania’s purpose is to drive the shift towards a sustainable transport system. We are convinced that we as a company, as well as the world of transport, can be fossil free before 2050 as agreed in the Paris Agreement on Climate.

To manifest our commitment and be transparent on progress, we have set science based carbon reduction targets (SBT), that commits us to reduce emissions at the scale and pace science dictates necessary to limit global warming.

This commitment represents a radical leap in our carbon reduction aims, as the targets encompass not only emissions from our direct global operations, but also from our customers' vehicles when in use.

They are fully aligned with our corporate targets – and will impact on investment decisions across our business areas, from production and logistics to product development and sales priorities. But it does not stop there. To be able to reach the targets Scania’s customers will need to manage their operations with less climate impact than their competitors and the industry at large.

Scania: Green House Gas Inventory

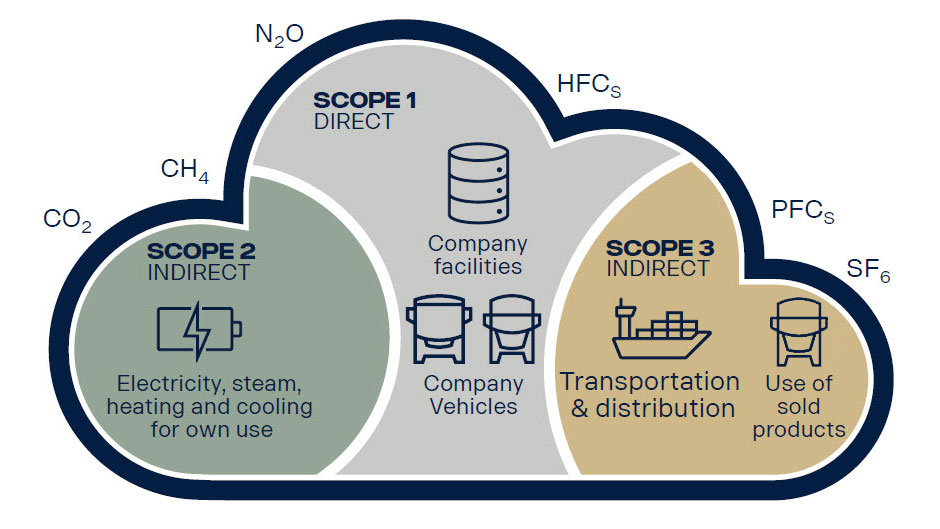

When calculating the climate impact from Scania, the Green House Gas Protocol is used. The GHG Protocol is the most commonly used global standard to measure and manage greenhouse gas (GHG) emissions from business operations, value chains and mitigation action.

The GHG protocol takes several greenhouse gases into account, not only carbon dioxide (CO2) but also methane (CH4), nitrous oxide (N2O), hydrofluorocarbons (HFC), perfluorocarbons (PFC) and sulfur hexafluoride (SF6).

The protocol divides a company’s emissions into scopes where direct carbon emissions from our own operations such as burning of fossil fuels for heating, engine testing and company vehicles are Scope 1 and indirect emissions generated by purchased electricity, heat and steam are Scope 2.

Scope 3 are our indirect value chain emissions. These include all emissions generated from the production of parts and components in the supply chain to the use of our products and all the way to end of life.

Our Science Based Targets cover all our Scope 1 and Scope 2 emissions as well as the emissions from when our products are being used (Scope 3). The latter category alone stands for more than 96 percent of our total emissions.

At Scania we have also set carbon reduction targets covering our global land transports (Scope 3, Transport & Distribution). We will reduce CO2 per transported tonne with 50 percent between 2015 and 2025.

Scania’s Science Based Climate Targets

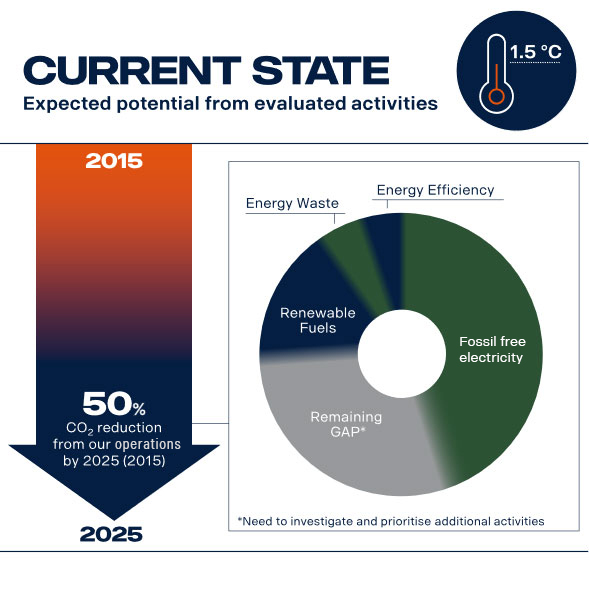

Scope 1 & 2

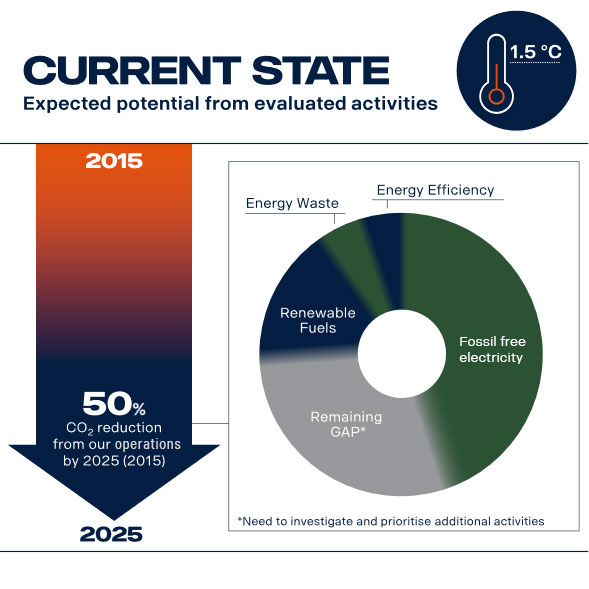

Scania will reduce its Scope 1 and 2 emissions with 50 percent until 2025 with 2015 as the base year in absolute terms. Thus, CO2 emissions from these scopes will be cut in half regardless of how much we grow. Activities include energy efficiency measures, transition from fossil fuels to biofuels and fossil free energy contracts.

Our Fossil Free Electricity target for 2020 (2010) and Energy Efficiency Target of 33 percent/vehicle 2020 (2010) are building blocks to this target.

According to Science Based Target initiative (SBTi), a 50 percent reduction in Scope 1 & 2 during this ten-year period is very ambitious and in line with a 1.5 degree scenario – the most stringent decarbonisation scenario in SBT.

Scope 3

More than 96 percent of the carbon emissions from our business is generated when products are in use. Scania always measures the actual climate impact during the use of its products, Well-to-Wheel (WtW), also taking into account the emissions generated in the production of the fuel or electricity.

According to the Science Based Target initiative (SBTi), this target is far-reaching and aligned with the most ambitious decarbonisation scenario that has been developed by them.

This is an intensity target measured in CO2 equivalents per kilometre. Scania will measure the climate impact from its products by using operational data from all its globally connected trucks and buses. The target means that the vehicles produced in 2025 shall have 20% lower CO2 emissions per kilometre compared to the vehicles produced in 2015. We will collect data from individual trucks and buses during one year and use it to analyse actual energy consumption and the amount of kilometres travelled. We will then add information about the type of energy that have been used to calculate the climate impact.

How Scania will Reach the climate targets

50% CO2 reduction from our operations by 2025

In order to cut the emissions from our operations with 50 percent between 2015 and 2025 we need to work with several activities. One of Scania’s core values is to Eliminate Waste and this is where it starts.

Another important part is energy efficiency measures by continuously investing in machinery and appliances that uses less energy than the ones they replace.

Last, but not least, after having taken out all that energy waste, we continually examine the opportunities for converting our use of fossil energy to renewable energy in our production and in our R&D activities. The electricity provided to our global production is already today fossil free (since 2020) and this is continuously expanding in our commercial network of workshops globally.

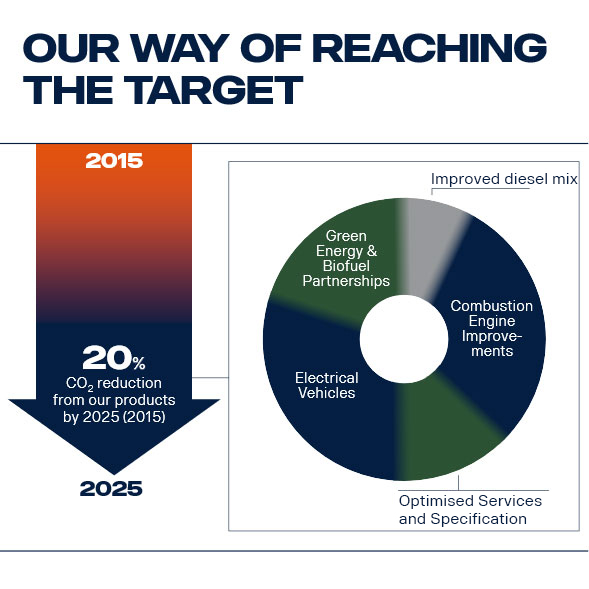

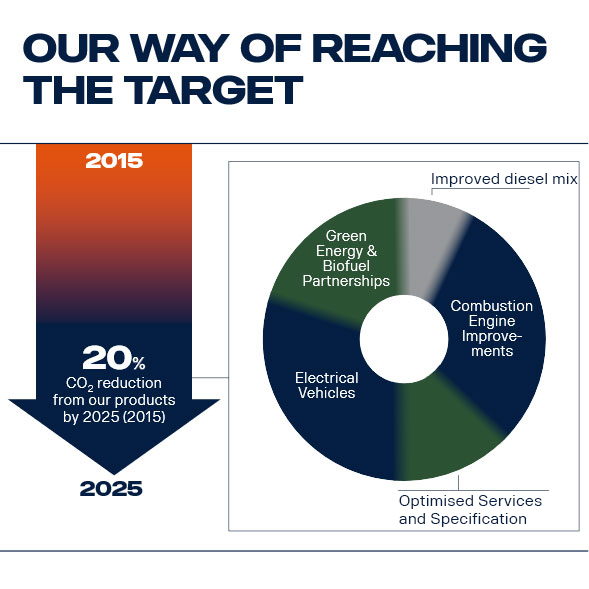

20% CO2 reduction from our products

There are four main blocks of activities that will help us reach the Science Based Target for Scope 3 – Use of Products.

In the years ahead we will introduce further efficiencies in our traditional product. One major contributor will be the new powertrain and connected components.

Together with our customers, we also need to find efficiencies through optimised specifications (better dimensioned powertrains, better tyres and so on) and by ensuring that the vehicles are driven more efficiently (driver services such as training and coaching).

This block also includes the shift to renewable sources of fuel or gas for the combustion engine. A vehicle running on biogas can reduce Well-to-Wheel (WtW) emissions by up to 80% here and now compared to a fossil diesel equivalent. We will accelerate this through increased partnerships in the transport ecosystem and by working closely with customers, transport buyers, infrastructure providers, fuel providers and other decision makers.

A fast transition to electrification is key in the shift towards a more sustainable transport system. Already today we offer plug-in hybrid buses and trucks and fully electric city buses and trucks for urban applications. Electrified vehicles running on the European electricity mix will halve CO2 per km emissions.

Finally, we need to ensure that the electricity used in our electrified products comes from renewable sources. Electrified vehicles operating on green electricity will reduce CO2 emissions by up to 98% compared to a conventional diesel vehicle running on fossil fuel.