Scania Opticruise gearbox range and MACH

Want to be contacted for a personal meeting or call with a Super expert?

Scania Opticruise G25 and G33

Industry-leading engine performance demands a highly-efficient gearbox. The Scania Opticruise gearbox range, available in two performance steps G25 and G33, set the highest industry standard for gearbox performance.

This is the Opticruise gearbox and chassis

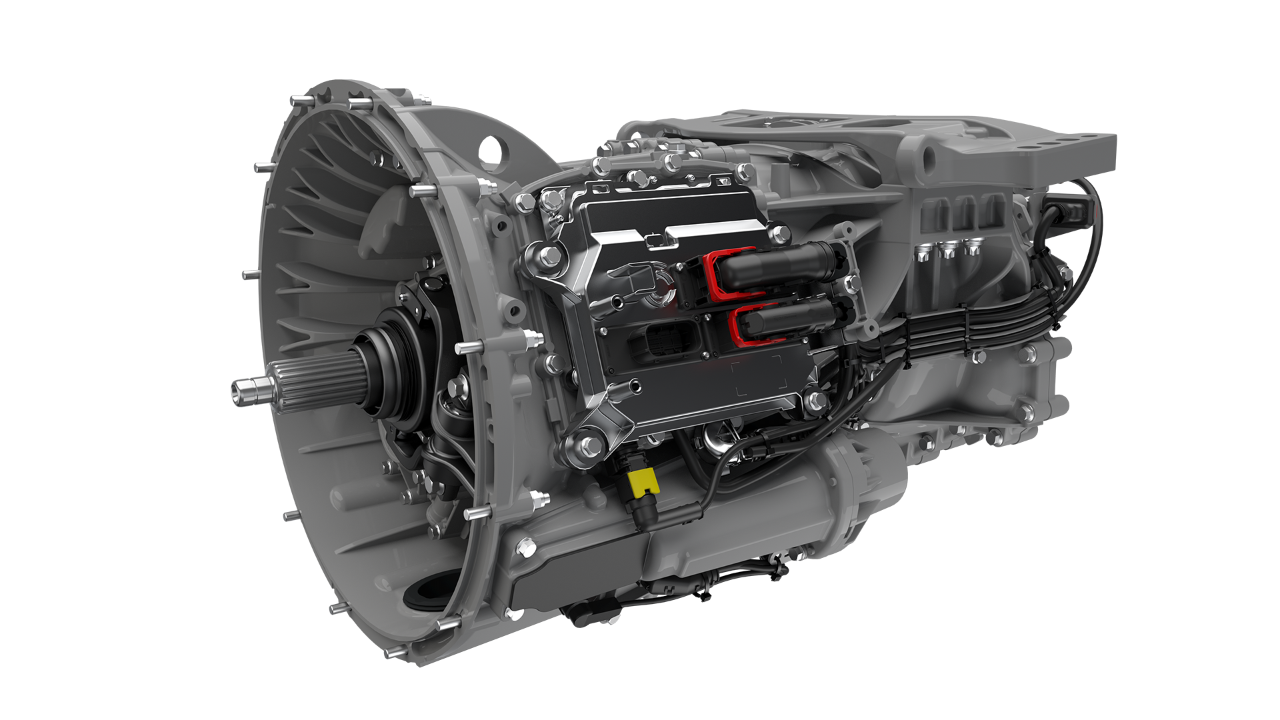

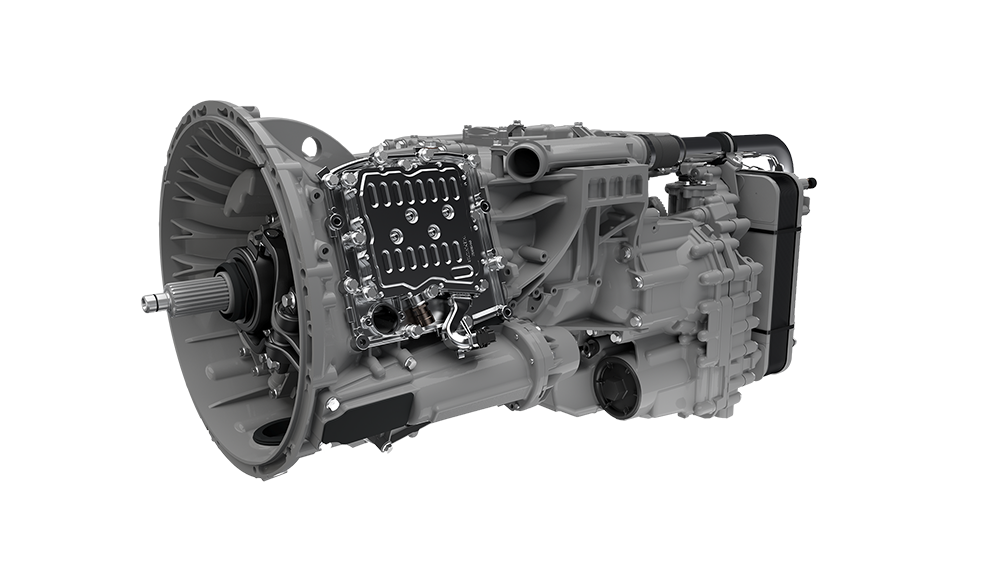

Opticruise gearbox

As a truly integrated part of the overall powertrain management, the Opticruise’s wider gear ratio spread, together with faster axle gearings, combine to deliver an almost seamless transfer of power across the Super powertrain and enable higher engine torque at lower RPM.

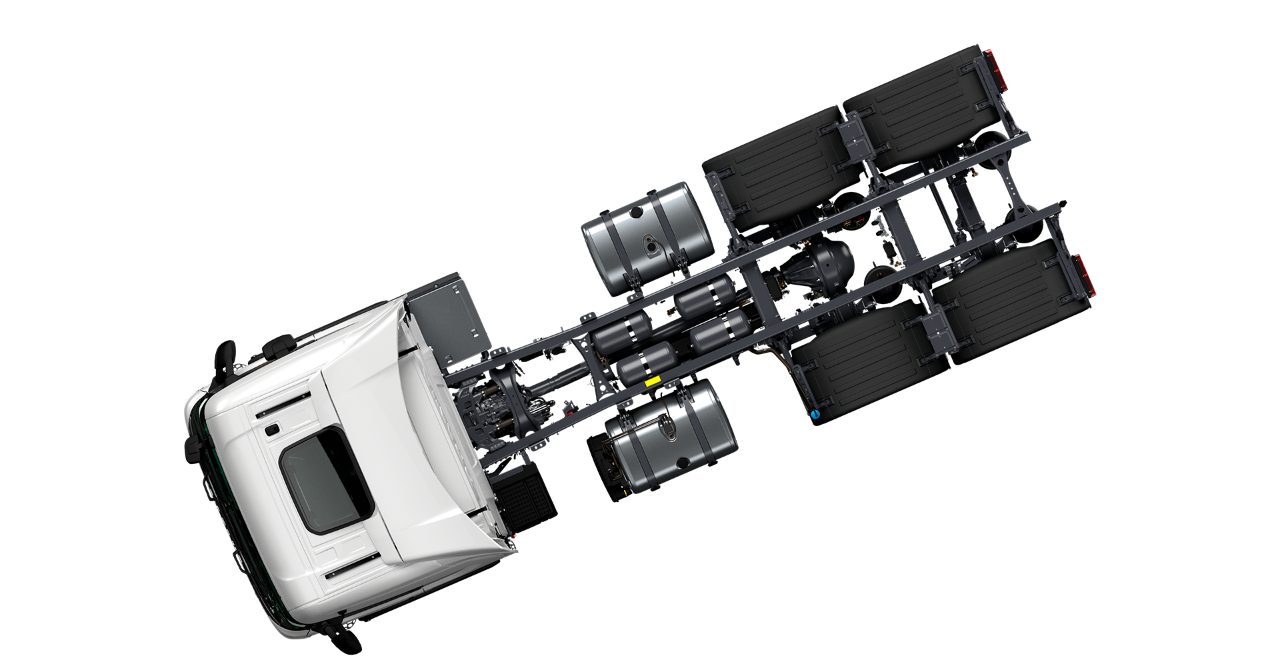

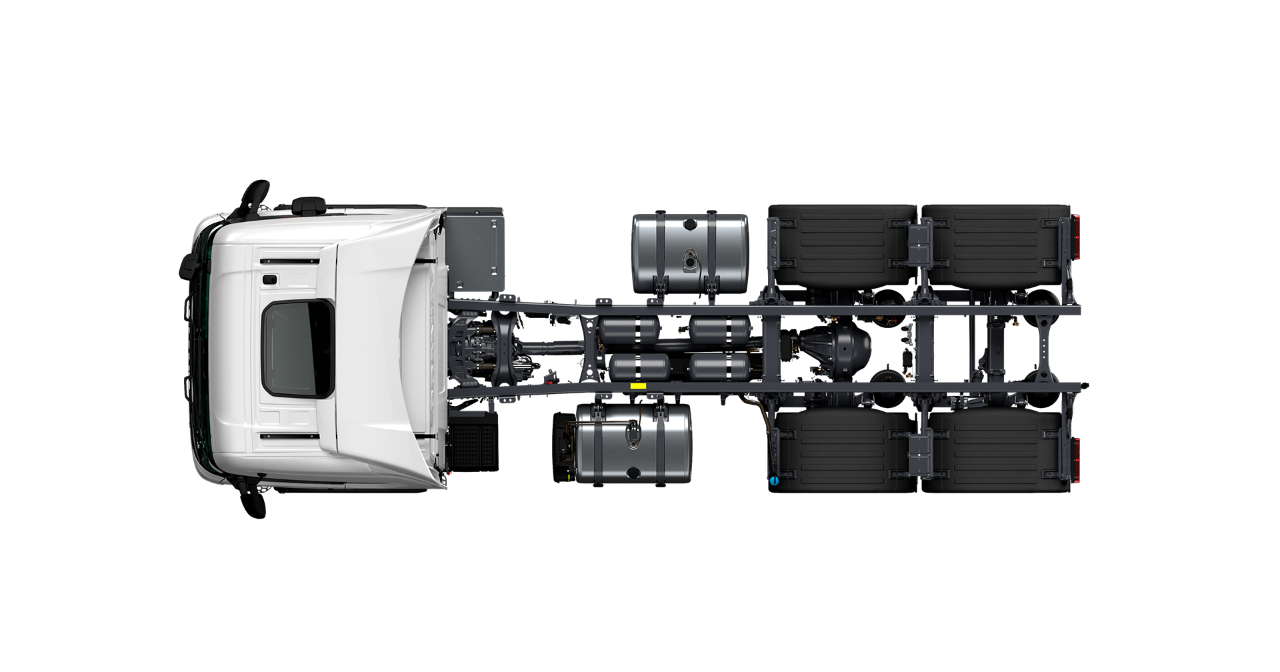

Chassis

Scania is introducing its most versatile and robust chassis yet. Based on the Scania modular system and offering a more predictable chassis layout, MACH, Scania’s Modular Architecture Chassis, gives you more opportunities to specify and operate your Scania truck in a way that is truly tailor-made for its application and your business.

Scania Opticruise gearbox G25 and G33

As one of the smoothest, efficient and smartest gearbox systems on the market, the Scania Opticruise remains the leading choice for sustainable, fuel-efficient transport operations.

- Faster, smoother gearchanges, giving outstanding comfort and control

- Combines good startability with slow rear axle gear ratio

- Available in 12+2 speed versions, with crawler and overdrive

- Up to 8 reverse gears designed for optimal engine speed regardless of high or low vehicle speed

- Wide ratio spread ranging from a crawler gear, ratio 1:20,8 to an overdrive gear ratio of 1:0,777

- Adaptive shift strategy based on style of driving, load and inclination of the road

- Longer service intervals, resulting in higher uptime and reduced costs

- Oil change intervals are now greatly improved due to higher precision and the addition of larger oil filters and high-quality oil

- The Scania Opticruise G25 and G33 deliver a more powerful, fuel-efficient, low-noise and low-weight clutch-driven power take-off (PTO) range, offering even higher continuous power output to support heavier equipment

Scania’s Opticruise gearbox is key to realising the fuel-saving potential of the Super engine platform. Light, compact, smooth and quick, it is the perfect match for the 13-litre engines.

When Scania’s engine developers were pushing the limits to create the cleanest and leanest combustion engine platform the world has ever seen, they had to give it the best possible conditions to fulfil its full potential. That’s why, even at an early stage in the development project, there were tight connections between Scania’s engine developers and their transmission and gearbox colleagues.

“This approach made it possible for us to design the powertrain totally from scratch, with a holistic perspective,” says Peer Norberg, Senior Engineer in Scania’s transmission development team.

Per Arnelöf, Expert Engineer, Scania gearbox development, adds:

“It was extremely motivating for us to have the initial discussions with the engine technicians and to realise how far you can actually go with an internal combustion engine when it comes to efficiency. From the very start, our focus was not only on designing a cutting-edge gearbox, but to optimise the whole powertrain to meet the customers’ demands.

“Many features of the G25 gearbox were introduced already with the G33 but what’s great is that we manage to take it a step further; for example, when it comes to reducing internal losses,” says Norberg.

Arnelöf adds: “The gearbox changes gears in a fantastic way. It’s responsive, quick and smooth. And as we also worked on the sound characteristics, it’s also very quiet; it doesn’t have the predecessor’s hisses and clanging.”

A key feature of Scania’s gearbox platform is its increased gear ratio spread: 60 percent more than the previous GRS905 model. This makes it possible to optimise the rear axle gear for low engine revs in cruising speed without sacrificing startability. That’s good news for fuel consumption and the climate.

“We make it possible to take further steps towards low engine revs. You can cruise on the highway at 80 km/h on gear 12 and then shift to overdrive in slight downhill conditions, coming down to an amazing 850 revs,” says Arnelöf.

“The gearbox is instrumental for enabling the engine to run as efficiently as possible. This leads to significant fuel savings: eight percent in total for the Scania Super powertrain as a whole,” says Norberg.

Chassis

Designed to give you an easier bodybuilding process, but it can significantly improve load distribution, payload potential and the operative range of your Scania truck.

Robust fuel tank range

Scania introduces a range of aluminium D-shaped fuel tanks, ranging from 165 litres to 910 litres and featuring a geometric design which is lighter and more robust than ever.

Harness more fuel than ever before

When specified with the Scania Super 13-litre engine, the fuel tank range comes with a fuel optimization unit fitted to the side wall, offering easy access to service points and the ability to increase the usable fuel volume in the tank. This reduces your tank’s dead weight, giving you a longer operative range and ensuring that you can harness more fuel from your tank than ever before.

Improved AdBlue ratio

Scania’s side-mounted SCR tanks are a crucial part of the Scania powertrain’s superior emissions control. The Scania Twin SCR system introduces higher AdBlue volume capacity, delivered through 123-litre and 150-litre SCR tanks, to continue ensuring a full 1:1 volume ratio between your Scania truck’s fuel and AdBlue capacity.

- The chassis introduces a set of rules for frame hole patterns, with dedicated holes for mounting parts both inside and outside the frame. The result is a more modular and predictable chassis layout, increasing the theoretical number of chassis layouts exponentially.

- The chassis layout enables more usable fuel and a 1:1 SCR/fuel ratio to be achieved, producing a greater operative range.

- The chassis’ optimised fuel capacity and load distribution also results in an increased payload for our customers.

- Improved chassis composition flexibility allows for better integration between truck and bodywork. This facilitates a much smoother and more cost-efficient bodybuilding process, as well as improving traction, payload and productivity. For example, the layout now makes it possible to mount chassis components (e.g. fuel tank) starting either from the front- or the rear axle. The improved weight distribution can significantly increase payload potential, while at the same time creating free space for additional chassis components.

Smaller, smarter, lighter and more efficient. Alongside Scania Super, a flexible chassis and tank programme is introduced, making it possible for the truck to reach the same or even greater distances with smaller fuel tanks. Here’s how it all comes together.

When it comes to developing the most energy-efficient truck the transport industry has ever seen, everything counts. Which is why Scania has put considerable resources into developing a new flexible chassis and tank programme, which plays an important part in realising the full potential of the new engine range, aftertreatment system, gearbox and rear axles.

“The tank programme enables us to maximise the uptake of fuel in the tank. Our philosophy during the development project was: “Why carry extra fuel as dead weight, when you can use it for load capacity instead?” says Aline Ferraz Larsson, a design engineer at Scania R&D.

The chassis and tank programme features D-shaped fuel tanks made from aluminium. The tanks are more robust yet also lighter, and their design increases fuel utilisation. Side-mounted SCR tanks are also included. All of this increases the vehicle’s uptime.

At the same time, Scania’s developers have improved the flexibility of the frame and the chassis composition.

“This gives the customer more choice for where to place the tanks on the frame, which is a great improvement for both them and truck body builders, since it creates opportunities for more efficient load distribution,” says Paula Pukk, Scania’s Head of SCR System Installation.

One of the keys enablers of Scania Super’s unmatched efficiency is the clever fuel optimisation unit. This unit is attached to the primary tank and works as a catch tank.

“The way that the catch tank is set up with electrical pumps enables the user to have ‘fuel on demand’: we get exactly the amount of fuel the engine needs, and no more,” says Alex Elofsson Alenius, a development engineer who worked on the project.

The fuel optimisation unit brings a host of other improvements for customers, and for the overall performance of the powertrain. There are now longer service intervals for the two pressurised fuel filters. These service intervals have been aligned with the oil change intervals, which means fewer visits to the workshop and more time on the road.

Scania MACH example configurations

R-series 500 Hp B4x2

Information about this configuration goes here

G-series 560 Hp XT 8x4

Information about this configuration goes here

P-series 420 Hp B4x2

Information about this configuration goes here

Field test with the Scania R-series 560 XT

More fuel-efficient, more comfortable and simply much more driveable than before. The Super powertrain has made life that bit easier for haulier Fermgruppen AB and driver Frida Lautin in the daily transport of timber in the forests of northern Sweden.

Tree after tree after tree. It’s all you can see for miles around when you travel through the countryside of Västernorrland and Gävleborg County in northern Sweden - because this is one of the main hubs of the forestry industry in a country that is the world’s third-largest exporter of wood pulp, paper and sawn timber.

Sundsvall-based haulier Fermgruppen AB is one of the many haulage companies that link together the supply chain of the forest products sector, which in 2018 generated 145 billion Swedish kronor in exports.

Each day, Fermgruppen’s trucks drive deep into the forests surrounding Sundsvall, picking up sixty-ton loads of logs from the nimble wood grabbing machines that follow in the wake of the heavy loggers that cut down trees with surgical precision.

Richard Ferm is the owner of Fermgruppen. Growing up, he always wanted his own trucks. He’s fulfilled his ambition, but working in a demanding business where margins are getting tighter all the time, he´s under no illusions.

He says it’s essential that the trucks are fuel-efficient, but that they also have all-weather reliability on rough, unpaved forest tracks that are constantly changing according to the conditions:

“The most important thing about a timber truck is that it has to get you into the forest and back again. The truck must be reliable. We’re often driving without phone coverage and have to use a radio link between the trucks in case one of them has problems.

“The vehicle must work when it’s hot and dusty, and it must also work when it’s cold, icy and snowy. It’s also about security for the driver. They need to be safe on the road, and there are often narrow roads with loose shoulders.”

The truck that Fermgruppen is testing is a 13-litre Scania 560 R XT with G33 gearbox. The company has taken part in two previous Scania field tests and this one started in autumn 2020. So far, Richard Ferm is happy with how it is going.

“I have been out driving the truck several times and the main positives I can see apart from the better fuel consumption are the driveability and the driver environment – it runs very quietly in the cab. I also find the gearbox to be a benefit.”

Driver Frida Lautin feels that the importance of the Super powertrain’s driveability cannot be overstated. After all, her daily drives involve high mileage, bad roads and frequent stops and starts, as she waits in the middle of the forest for other trucks to be loaded with timber.

“It´s very quiet in the cab, and it’s stable to drive and does not bounce, which is nice for the body as well. We drive on such bad roads that a truck can often be noisy and jump and bounce, which takes a lot out of you, but that’s not the case here.”