Island - 1

Super operating economy

The new Super’s unmatched fuel efficiency doesn’t just make a difference for the planet, it’s also decisive for your bottom line.

For example, a general cargo haulage operator that clocks up an annual vehicle mileage of 130,000 km can save approximately €3,000 in annual fuel costs* per vehicle. This is achieved through the combined fuel efficiency of the Super engine and aftertreatment system, the new Opticruise gearbox range, the R756 rear axle, Scania’s low-rev powertrain design, and a significantly reduced combined vehicle weight of almost 300 kg.

When you combine this with the powertrain’s increased operative range, superior technical robustness and extended component life length – meaning that you can keep your business on the road for longer than ever before, with fewer pitstops – you get a truck which offers the strongest total operating economy in the history of transport.

*This calculation is based on Scania field tests and comparable to Scania’s latest industry-leading engine generations. Estimated fuel savings will vary depending on operation type. This figure is calculated using an average diesel cost of €1,10/litre.

Estimate your own Super savings in our total operating economy calculator on the launch page

“We couldn´t believe the fuel consumption figures”

With its incredible fuel efficiency and superior driveability, the new 13-litre Scania 560 S truck tested by Herbert Ulfhielm Fjärrtransport could be the answer to hard-pressed hauliers’ prayers.

The fuel consumption levels of the new 13-litre Scania 560 S that’s being tested by Herbert Ulfhielm Fjärrtransport are really low. So low compared with other trucks that, at first look, the driver Jerry Olofsson and the company’s co-owner Lars Åström thought they’d made a mistake. But they were in for an amazing surprise.

“You are used to trucks where if you get under 40 litres per 100 kilometres, then you are quite happy. But during the latest trips now, I’ve sometimes been below 34 or even 33 litres – and that’s with the truck loaded with heavy timber products. The first time I checked it and counted it myself, I thought: ‘I must have forgotten to log some refuelling’,” says Jerry, who’s been driving trucks for 23 years; the past ten with Ulfhielm.

Twice a week, this friendly, chatty driver makes the 7.5 hour, 500-kilometre drive over the mountains from the Swedish city of Skellefteå to the Norwegian port of Bodø, hauling timber products. The next day, he heads back to Sweden, loaded with deliveries of waste products for use in district heating systems, as well as wood chips and tyres. The truck is his ‘office’ and achieving good fuel economy is always an important consideration in his work.

“During the winter, the truck always uses a little more when the truck is idling because it’s much colder and the truck is heavier,” he adds.

“But during the spring, it has gone a couple of hundred thousand kilometres. We started to notice that there the fuel figures are low, so I called my boss Lars and asked him if he’d checked it! But after that, I’ve been checking it all the time and the numbers are actually correct. And it's fun! Because I’ve not changed my driving style; I have just been driving as I usually do.”

“I was surprised because the difference was so big,” says Lars.

“It’s about six litres every 100 kilometres, and some weeks there has been an even bigger difference between our Scania R 490 and this one. The 490 has been at around 38 to 40 litres and this one has been fairly constant lately at 32 to 33 litres. Bear in mind that we still do not really drive the best roads and most of the time we’re carrying loads of up to 60 tonnes.”

“We have had several other field test trucks that were efficient, but there has never been a truck that has made as big a difference as this one now. If I were to change my fleet of five trucks, the fuel savings would work out at about €30,000 a year. For my company, that’s the equivalent of the instalments for another truck.”

That’s a welcome boost to the company’s profitability in an industry with increasingly tight margins.

Island - 2

Class-leading efficiency

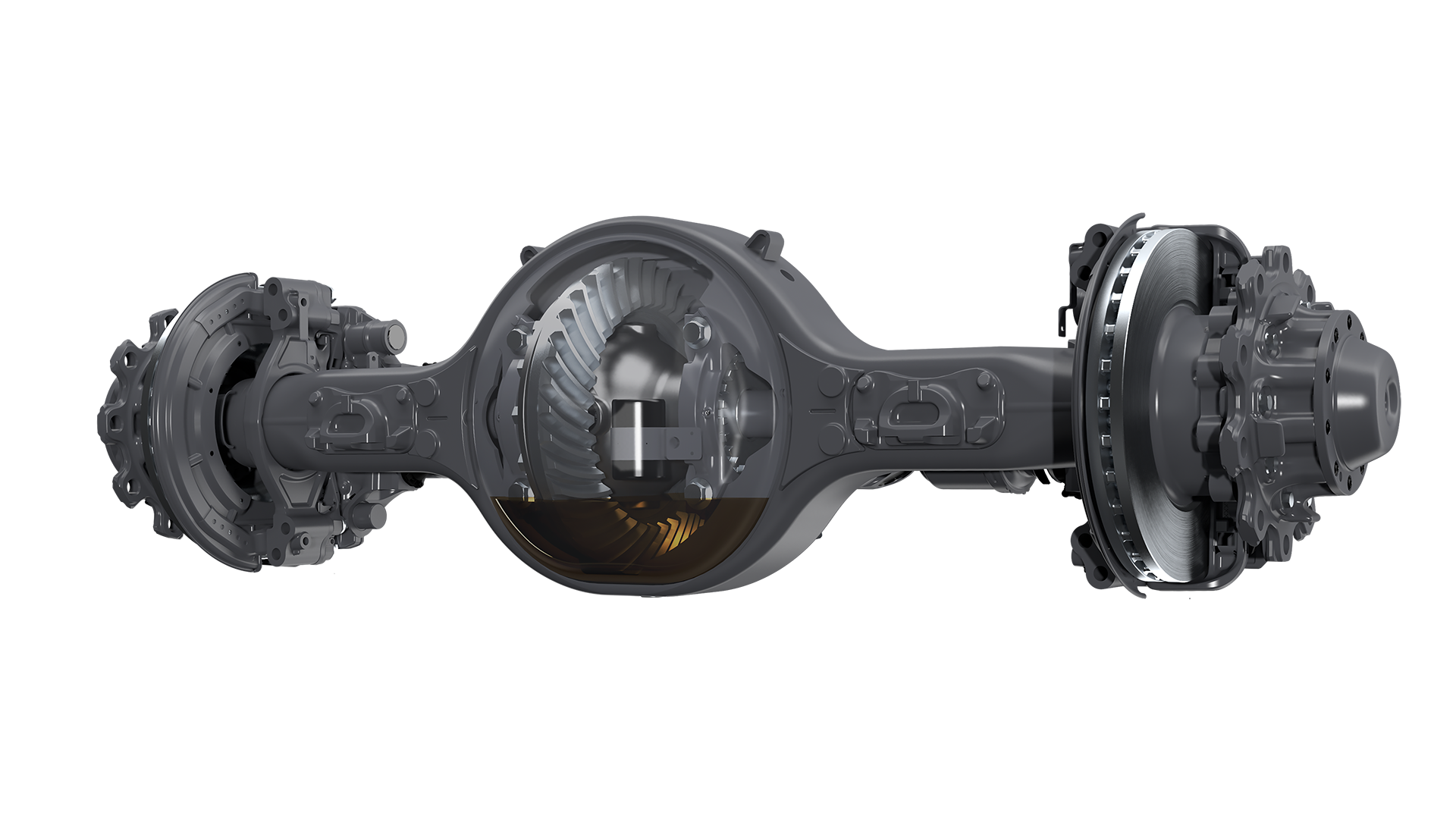

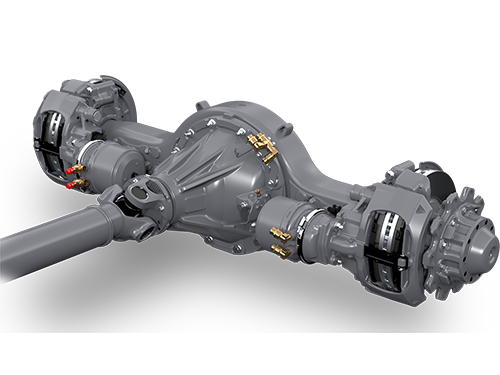

Delivering on the powertrain’s fully integrated low-rev design philosophy Scania introduces the faster-gearing R756 single reduction rear axle – offering a wider range of gear ratios from 1.95 to 4.11, and purpose-designed to enable the exceptional fuel efficiency of the Scania Super powertrain.

Together with reduced component weight, improved technical robustness, and lower levels of internal friction, the Scania R756 single reduction rear axle is versatile enough to master a whole range of haulage applications.

The operational difference

Learn about the new axle

- The Scania R756 single reduction rear drive axle replaces the Scania R665, Scania R753 and most Scania R780 axle applications, serving a wide range of vehicle operations up to a gross train weight of 53 tonnes, from light long haulage to tippers and refuse collections.

- The improved robustness of the Scania R756 is designed to deliver an increased operational service lifetime, as well as extended service intervals.

- R756 offers a reduced component weight of up to 27 kilograms compared to the Scania R780 single reduction rear axle.

- Permanent oil filter enables reduced maintenance cost and contributes to an extended oil change interval by as much as 50%, depending on your operation type.

Fit for the world’s best powertrain

Lower energy losses. Improved efficiency. One percent fuel saving from the rear axle alone. Even more to gain thanks to the full integration with the new gearbox, making it possible to utilise faster rear axle gears. Scania’s team of axle developers has done it again.

Where would Scania’s low-rev and high-torque philosophy be without the cutting-edge components and software that make the complete truck greater than the sum of its parts? Well, it wouldn’t be Super if each piece wasn’t super too.

That’s why the developers and construction engineers at Scania Technical Centre in Södertälje, Sweden, have always had an eye on the most minute details: wherever there is greater efficiency to be obtained, wherever there are grams that could be cut to make it lighter, wherever there is friction to reduce, wherever there is a penny to save for the customers, it’s worth pursuing.

Scania’s new rear axle gear is no exception to this perfectionism.

“We’ve managed to present a killer component. This is a rear axle that fits the world’s best powertrain,” says Torvald Ilg, Chief Engineer within Axles and Propulsion Development at Scania and one of the developers that has been working on the rear axle programme.

“It’s great to design a component that makes the driver a bit happier each time he or she fills up the tank,” he adds.

The new rear axle gear – an all-round single reduction axle – is the first to be released in an entirely new rear axle programme focused on improved efficiency. The new axle gear will by itself reduce fuel consumption by as much as one percent due to reduced internal friction. And together with increased gear ratio spread of the G33 and G25 gearboxes, there is the potential for additional fuel savings.

So, how did Scania’s R&D team manage to improve the efficiency of the new rear axle? The axle housing is new and lighter than the previous model. Special, low friction bearings are used throughout, which is especially important on the pinion gear. What’s more, the parts have tighter tolerances and are more smoothly machined in production, leading to minimal energy losses.

Torvald Ilg also says his team has had close contact with the other Scania developer teams, who are focusing on the new 13-litre Super engine platform, the new gearbox, as well as the new tanks and flexible chassis, respectively.

Island - 3

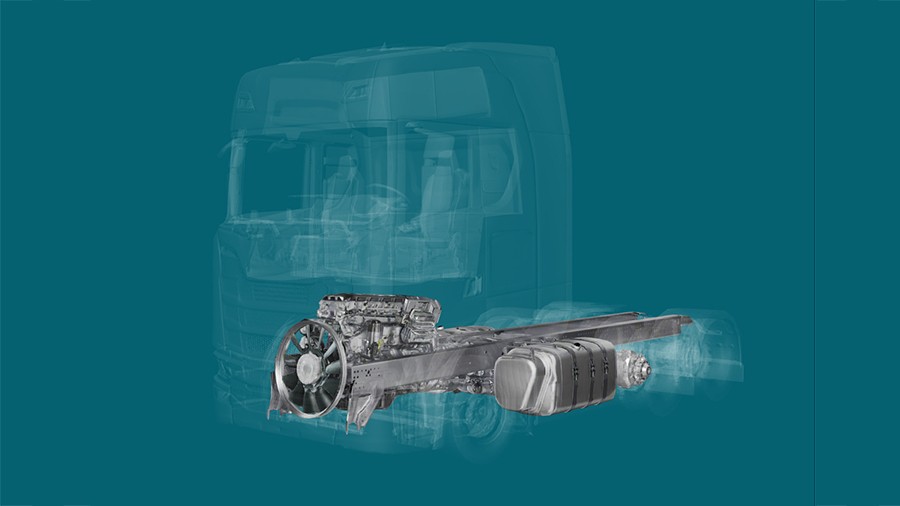

Scania’s most efficient powertrain yet

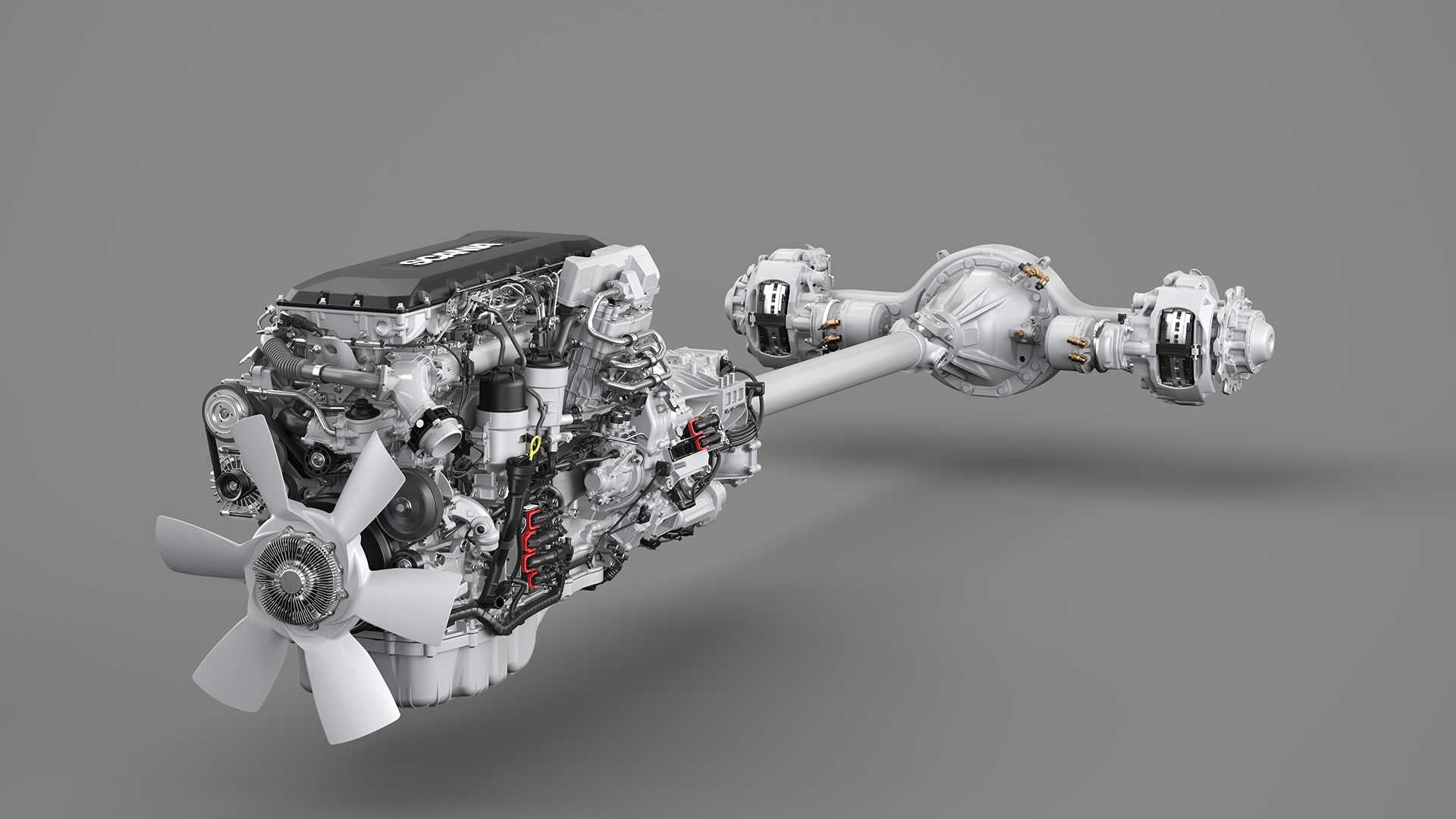

The powertrain’s groundbreaking efficiency really is the sum of its different components: the Scania Super 13-litre inline 6-cylinder engine, the Scania Opticruise gearbox, and the Scania R756 single reduction rear axle. It is also complemented by the introduction of Scania’s most versatile chassis yet – with increased modularity to facilitate a smoother bodybuilding process and optimal load distribution.

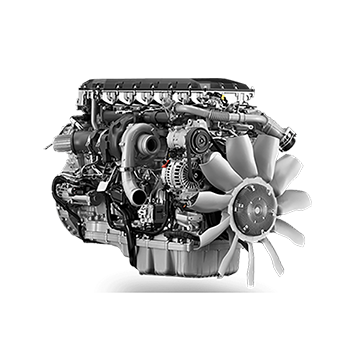

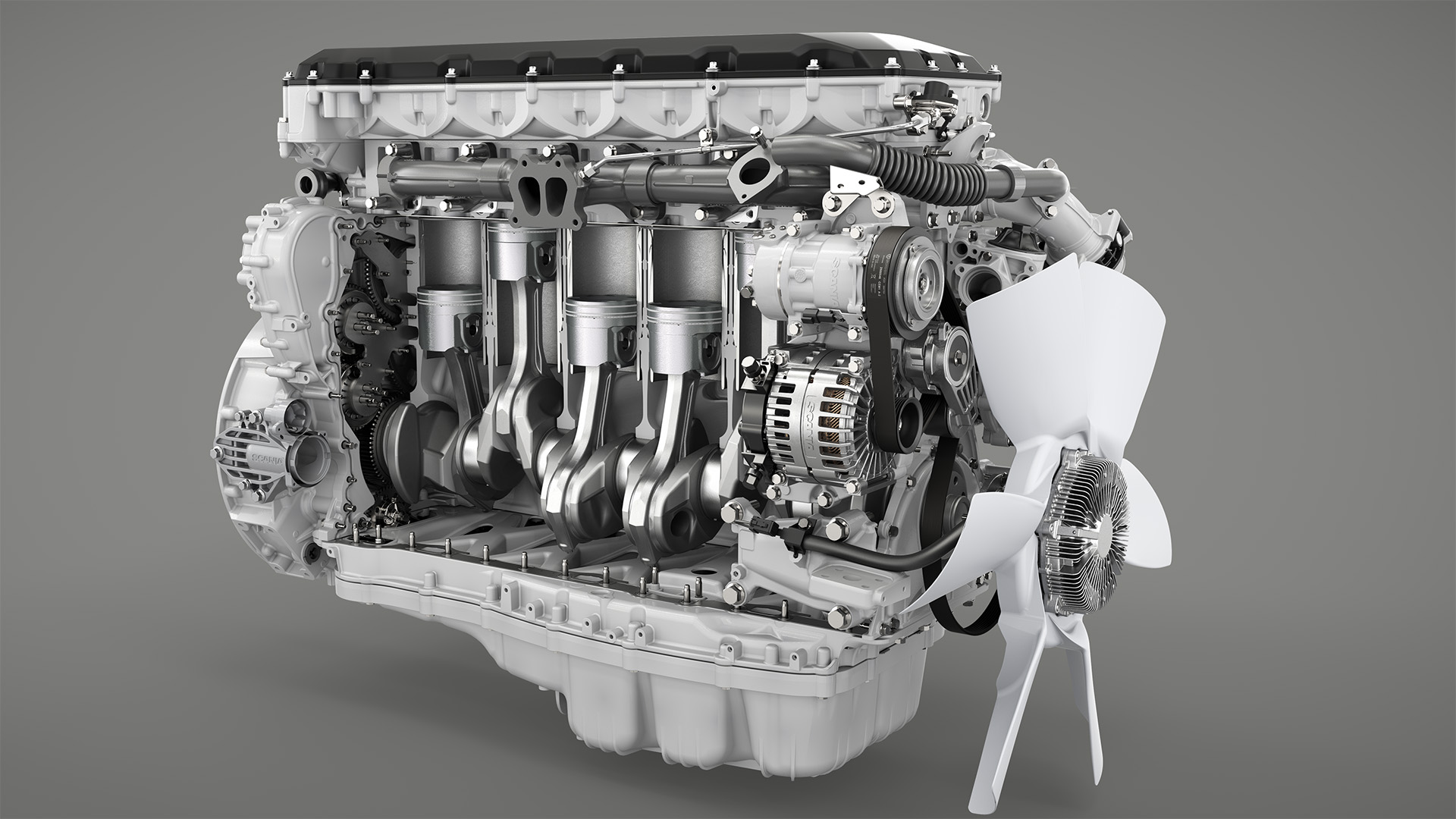

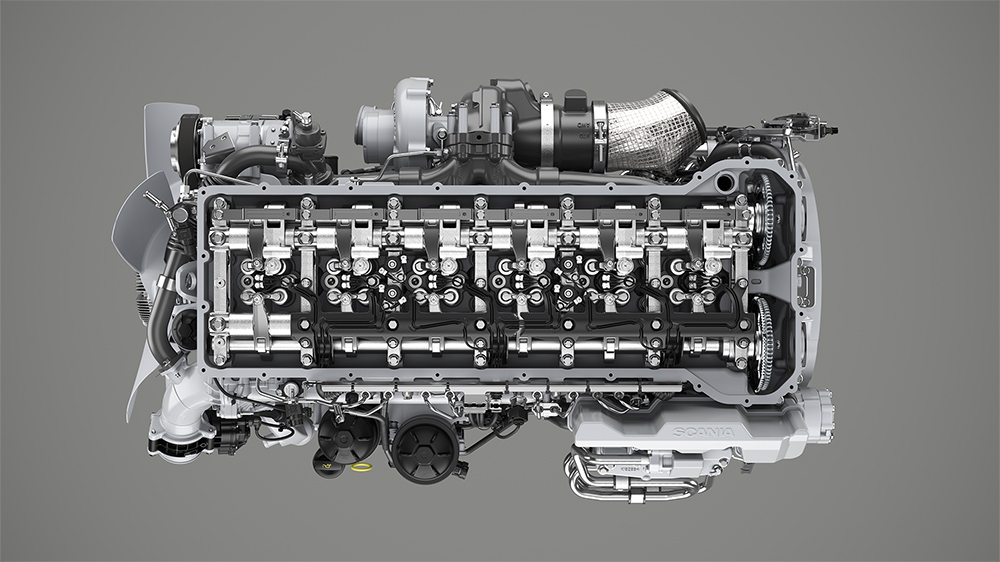

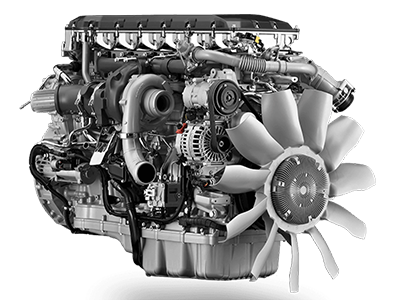

Scania Super 13-litre engine

Serving as the heart of a powertrain that sets a new industry-leading fuel economy standard, the new Scania Super becomes the most advanced combustion engine we have ever built.

Behind the Super’s unrivalled performance level lies significant improvements to the engine’s combustion and aspiration performance, lubrication and cooling, and turbocharging efficiency. It also features a range of industry-leading engine technologies, such as the Scania Twin SCR system, and a new, powerful engine management system to ensure the engine’s superior total operating economy under all conditions.

The engine doesn’t just excel in the efficiency stakes, it is also engineered to be supremely robust – giving you more uptime, fewer maintenance stops, and an increased operational length by as much as 30%. All of this combines to keep your business rolling further beyond the transport challenges of tomorrow.

Brake thermal efficiency

The Scania Super 13-litre engine sets a new benchmark for brake thermal efficiency at 50%, a level that was once thought to be out of reach for internal combustion engines.

Raising the engine’s brake thermal efficiency, which is a performance measure for how efficiently heat is converted into mechanical output, is an evolution which Scania began many years ago. In the 1930s, Scania’s earliest diesel engines produced an average thermal efficiency of about 30%, meaning that just under a third of the energy consumed was converted into mechanical output. Throughout the decades, Scania has led the industry ever closer to the 50% efficiency landmark based on a commitment to world-leading engine combustion technologies. Today, with the launch of the Scania Super and a new brake thermal efficiency benchmark of 50%, we are taking another monumental step on our journey toward sustainable transport systems.

Low rev, high efficiency

Ever since 1976, Scania has been committed to delivering peak torque at lower engine revolutions per minute (RPM). Not only does this ensure a smoother drive with fewer gear changes and less noise, but it is also vital to increasing the powertrain’s fuel economy.

The new powertrain takes this design philosophy a step further. Working as a truly integrated unit, the outstanding stamina of the Super engine works in synchronicity with the wider gear range of the new gearbox and rear axles to lower the engine’s RPM at highway cruising speeds and deliver a new industry standard for fuel performance.

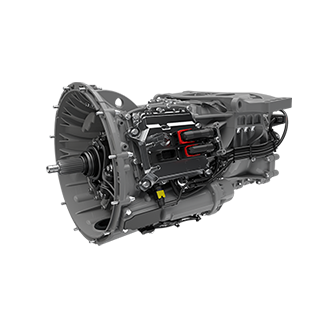

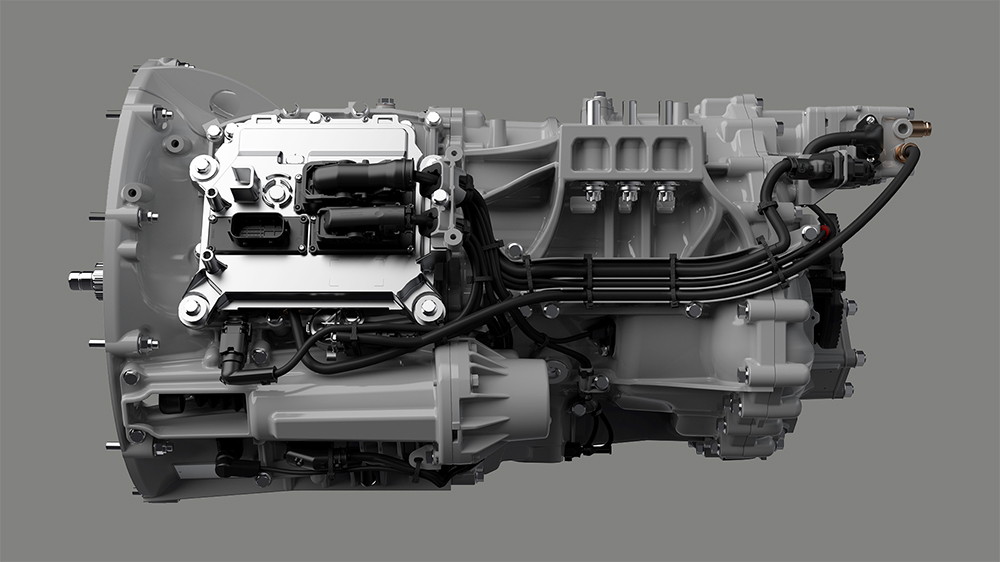

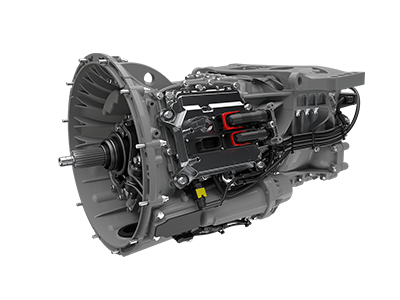

Opticruise G25 and G33

The Scania Opticruise gearbox range, now available in two performance steps G25 and G33, are indispensable to the Super powertrain’s superior fuel economy.

As a truly integrated part of the overall powertrain management, the new Opticruise’s wider gear ratio spread, together with faster axle gearings, combine to deliver an almost seamless transfer of power across the Super powertrain and enable higher engine torque at lower revs. As one of the smoothest, efficient and smartest gearbox systems on the market, the Scania Opticruise remains the leading choice for sustainable, fuel-efficient transport operations.

R756 rear axles

To deliver on the powertrain’s fully integrated low-rev design philosophy, Scania introduces the faster-gearing R756 single reduction rear axles – offering a wider range of gear ratios from 1.95 to 4.11, and purpose-designed to enable the exceptional fuel efficiency of the Scania Super powertrain.

Together with reduced component weight, improved technical robustness, and lower levels of internal friction, the Scania R756 single reduction rear axle is versatile enough to master a whole range of haulage applications.

New Scania mirror view camera

Learn about the new mirror view cameras

The introduction of the new powertrain also coincides with the launch of the new Scania Mirror View Camera (SMVC).

Scania has always been committed to raising driver and vehicle safety standards through world-leading technologies, and the SMVC is the next step on that journey.

As Scania’s latest vehicle accessory, the new SMVC system is a unique and optional camera solution that delivers enhanced driveability and visibility of your Scania truck. It ensures improved driver control in tight junctions and busy urban areas, even in the most challenging driving conditions. The system contains two synchronised cameras mounted on the lower attachment of the cab’s side mirrors and two 12.3-inch high-resolution monitors mounted on both A-pillars. The SMVC ensures a clear and enhanced line of sight through to the end of the vehicle, minimising the risk of blind spots and any potential hazards hidden behind the cab’s A-pillars, even in poor weather conditions.

Features and customer value

- Based on field tests, the SMVC is proven to significantly improve both direct- and indirect driver sight.

- The system delivers enhanced vision at night and features an “anti-dazzle function” to reduce the impact of strong external lighting.

- The SMVC’s monitor switches automatically between day- and night vision, ensuring optimal driver ergonomic and visual comfort.

- Both cameras are foldable and equipped with a lens heater to mitigate fog and ice, as well as a drip list to protect the lenses from rain.

- The system is designed to reduce the perceived total width of the cab, making it easier to drive, park and manoeuvre in all conditions.

- The system is engineered to align with Scania’s fuel-saving design, offering minimal air drag and thoroughly-tested aero dynamics.

- The low-position foldable cameras enable full direct driver control, minimising the risk of parking accidents in garages or loading centres.

Contact your local Scania dealer to find out more about the Scania Mirror View Camera.

“We've been waiting for this for years”

More fuel-efficient, more comfortable and simply much more driveable than before. The new Super powertrain has made life that bit easier for haulier Fermgruppen AB and driver Frida Lautin in the daily transport of timber in the forests of northern Sweden.

Tree after tree after tree. It’s all you can see for miles around when you travel through the countryside of Västernorrland and Gävleborg County in northern Sweden - because this is one of the main hubs of the forestry industry in a country that is the world’s third-largest exporter of wood pulp, paper and sawn timber.

Sundsvall-based haulier Fermgruppen AB is one of the many haulage companies that link together the supply chain of the forest products sector, which in 2018 generated 145 billion Swedish kronor in exports.

Each day, Fermgruppen’s trucks drive deep into the forests surrounding Sundsvall, picking up sixty-ton loads of logs from the nimble wood grabbing machines that follow in the wake of the heavy loggers that cut down trees with surgical precision.

Richard Ferm is the owner of Fermgruppen. Growing up, he always wanted his own trucks. He’s fulfilled his ambition, but working in a demanding business where margins are getting tighter all the time, he´s under no illusions.

He says it’s essential that the trucks are fuel-efficient, but that they also have all-weather reliability on rough, unpaved forest tracks that are constantly changing according to the conditions:

“The most important thing about a timber truck is that it has to get you into the forest and back again. The truck must be reliable. We’re often driving without phone coverage and have to use a radio link between the trucks in case one of them has problems.

“The vehicle must work when it’s hot and dusty, and it must also work when it’s cold, icy and snowy. It’s also about security for the driver. They need to be safe on the road, and there are often narrow roads with loose shoulders.”

The truck that Fermgruppen is testing is a 13-litre Scania 560 R XT with G33 gearbox. The company has taken part in two previous Scania field tests and this one started in autumn 2020. So far, Richard Ferm is happy with how it is going.

“I have been out driving the truck several times and the main positives I can see apart from the better fuel consumption are the driveability and the driver environment – it runs very quietly in the cab. I also find the new gearbox to be a benefit.”

Driver Frida Lautin feels that the importance of the new Super powertrain’s driveability cannot be overstated. After all, her daily drives involve high mileage, bad roads and frequent stops and starts, as she waits in the middle of the forest for other trucks to be loaded with timber.

“It´s very quiet in the cab, and it’s stable to drive and does not bounce, which is nice for the body as well. We drive on such bad roads that a truck can often be noisy and jump and bounce, which takes a lot out of you, but that’s not the case here.”

Island - 4

Redefining engine performance

Ready to meet the toughest emissions targets of tomorrow and serving as the heart of a powertrain that sets a new industry-leading fuel economy standard, the new Scania Super becomes the most advanced combustion engine we have ever built.

Behind the Super’s unrivalled performance level lies significant improvements to the engine’s combustion and aspiration performance, lubrication and cooling, and turbocharging efficiency. It also features a range of industry-leading engine technologies, such as the Scania Twin SCR system, and a new, powerful engine management system to ensure the engine’s superior total operating economy under all conditions.

The engine doesn’t just excel in the efficiency stakes, it is also supremely robust. The Super’s outstanding technical robustness is engineered to give you more uptime, fewer maintenance stops, and an increased operational life length by as much as 30%. All of this combines to give you unrivalled total operating economy and keep your business rolling further than ever beyond the transport challenges of tomorrow.

Ready for tomorrow

World-leading emissions control

The industry-leading Scania Twin SCR system is the centrepiece of the Super’s unmatched efficiency. Introducing dual dosing of AdBlue in the powertrain’s aftertreatment process, the Scania Twin SCR system makes it possible to redefine the limits of combustion performance, while still meeting future expected legal requirements with even higher demands on nitrogen oxide emissions.

Premium power and stamina

With a power range up to 560hp and torque up to 2800Nm, the Super delivers more power than ever before on a Scania 6-cylinder inline engine. It also features extreme stamina, producing effortless propulsion and peak torque at lower RPM.

Integrated auxiliary braking

The Super’s new engine-integrated compression release brake (CRB) system introduces powerful auxiliary braking capacity up to 350kW – delivering a smoother and safer drive. Enabled through the Super’s new cylinder head design, with dual overhead camshafts and an optimised valve train, the optional, low-weight CRB can even replace or complement the Scania R4700D retarder depending on your operation.

The operational difference

- Available in 420hp, 460hp, 500hp and 560hp

- Full torque available from 900 RPM for improved driveability

- Increased uptime due to longer maintenance intervals

- Better productivity and increased payload (with optional CRB)

- The possibility to add Active Cruise Control (AiCC) without retarder (with optional CRB)

- 2 new optional engine-driven PTOs offering increased torque up to 1000Nm and power output up to 238kW

- Integrated Management of the complete powertrain performance

Find out more by downloading the Scania Super engine brochure available in the “Download” section

The beating heart of the new powertrain

For the past five years, Scania’s super-dedicated R&D teams have turned over every stone to develop the most energy-efficient and sustainable combustion engine platform the heavy transport industry has ever seen. Here’s how they came up with the super-efficient Scania Super.

How do you improve on an engine platform that has won the European Green truck award five years in a row? How do you develop a powertrain that will strengthen Scania’s industry-leading position within sustainable transport for the rest of this decade?

The developers at Scania Technical Centre who were given these assignments say the answers are: determination, innovation and customer focus.

“Starting from scratch meant we could concentrate all our design work with the customers’ needs in focus, without restraints. That’s why we can now present a product that the transport industry really needs here and now to take the necessary steps towards a sustainable future,” says Assistant Chief Engineer Linda Pukk Berggren.

“Fuel consumption is significantly reduced for a very broad part of the engine speed and load area. This means that many different applications, such as long-haul, construction and forestry vehicles, will all benefit from the improvements and emit less CO2,” says Magnus Nilsson, Technical Manager within Aftertreatment.

Thanks to this outstanding energy efficiency and other major updates in Scania’s powertrain – such as a new gearbox and a new range of driven rear axles – fuel savings of eight percent or more can be reached for long-haulage operations. And that’s in comparison with Scania’s already industry-leading performance levels. Efficient just became super-efficient.

So, what’s ‘under the hood’ of the new 13-litre engine? Quite a lot, in fact.

New features include dual over-head camshafts, optimised injectors, improved combustion, an optimised high-pressure fuel pump, improved cooling and lubrication, increased turbocharger efficiency, and a state-of-the-art engine management system.

Not only that; Scania’s successful dual dosing Selective Catalytic Reduction system, which has been proven to offer excellent fuel saving capacity and increased productivity and uptime, has been remade from the ground up. The system has earned a name of its own: Scania Twin SCR.

Island - 5

The future is super

While no one can say for sure what the future will bring, we’re confident that it’s a bright one.

The groundbreaking new Scania Super not only ensures the smoothest drive on the road, but it is also the most efficient and robust combustion engine powertrain we’ve ever built. Delivering unrivalled fuel savings and more uptime than ever before, the Scania Super sets a remarkable new standard for efficient, profitable, and sustainable transport operations – mile after mile, load after load, year after year.

The future has never looked better. The future is Super.

Return of an Icon

In 1961, we mounted our first ever turbocharged engine, also known as supercharger, into a Scania-Vabis L75 truck. The rest, as they say, is history.

The debut of the turbocharged Scania DS10 engine became a milestone which marked a new era of combustion engine technology – one where power and efficiency could co-exist without compromise or contradiction.

Sixty years later, the Scania Super returns to raise combustion engine performance to unprecedented new levels and lead today’s transport industry through a new decade of challenges. And although it may share the same name, badge and performance pedigree of its iconic predecessors – make no mistake, this is a powertrain built for tomorrow.

Scania Super: 80 years of evolution

- 1951: Scania-Vabis launches its first turbocharged engine, using an 8-cylinder inline engine equipped with a turbine compressor. It is initially mounted in boats and rail buses, among other applications.

- 1961: Scania-Vabis launches a new turbocharged engine, the 10-litre 6-cylinder inline DS10 engine, designed for truck operations. Through turbocharging alone, the engine’s power increases from 165hp to 205hp. The engine achieves instant market success. The legend of the Super was born and has served as a symbol of powerful Scania engines ever since.

- 1976: Scania introduces its low-rev design philosophy, driven by a determination to deliver peak torque at lower engine revs for improved fuel economy and fewer gearchanges. This remains a hallmark of all Scania engines to this day.

- 1991: In Scania’s centenary year, the Scania DTC11 engine launches to become the world’s first production-ready turbo-compound engine for trucks.

- 2021: As Scania marks its 130-year anniversary, the new Scania Super launches to set a new benchmark for brake thermal efficiency and redefine the limits of combustion engine performance once again.

Island - 6

Next-level modularity

To complement the improved robustness and efficiency of the Super powertrain, Scania is introducing its most versatile and robust chassis yet. Based on the Scania modular system and offering a more predictable chassis layout, MACH, Scania’s new Modular Architecture Chassis, gives you more opportunities to specify and operate your Scania truck in a way that is truly tailor-made for its application and your business. Not only is this designed to give you an easier bodybuilding process, but it can significantly improve load distribution, payload potential and the operative range of your Scania truck.

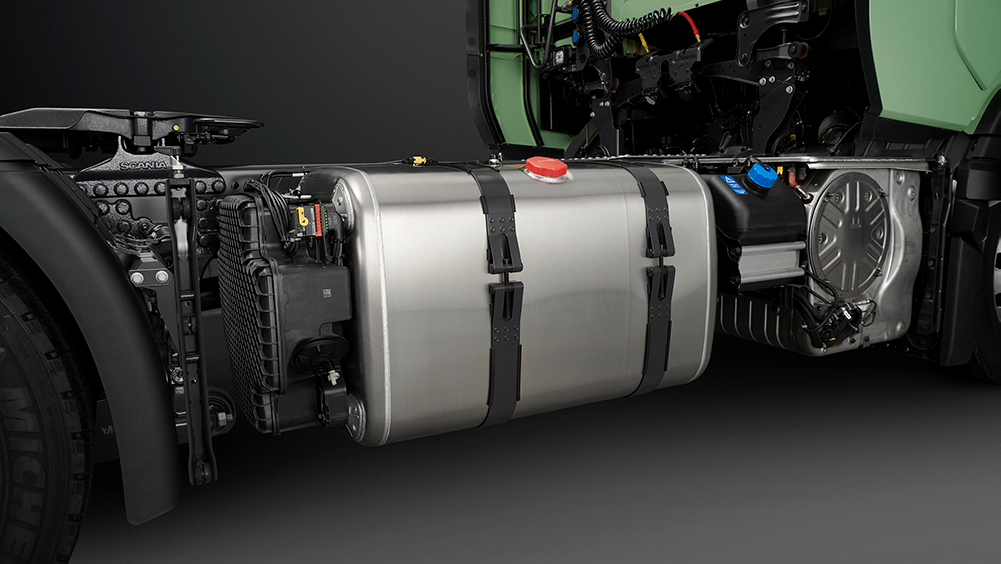

New robust fuel tank range

Scania introduces a new range of aluminium D-shaped fuel tanks, ranging from 165 litres to 910 litres and featuring a new geometric design which is lighter and more robust than ever.

Harness more fuel than ever before

When specified with the Scania Super 13-litre engine, the new fuel tank range comes with a fuel optimization unit fitted to the side wall, offering easy access to service points and the ability to increase the usable fuel volume in the tank. This reduces your tank’s dead weight, giving you a longer operative range and ensuring that you can harness more fuel from your tank than ever before.

Improved AdBlue ratio

Scania’s side-mounted SCR tanks are a crucial part of the Scania powertrain’s superior emissions control. The Scania Twin SCR system introduces higher AdBlue volume capacity, delivered through 123-litre and 150-litre SCR tanks, to continue ensuring a full 1:1 volume ratio between your Scania truck’s fuel and AdBlue capacity.

The operational difference

- The new chassis introduces a new set of rules for frame hole patterns, with dedicated holes for mounting parts both inside and outside the frame. The result is a more modular and predictable chassis layout, increasing the theoretical number of chassis layouts exponentially.

- The new chassis layout enables more usable fuel and a 1:1 SCR/fuel ratio to be achieved, producing a greater operative range.

- The new chassis’ optimised fuel capacity and load distribution also results in an increased payload for our customers.

- Improved chassis composition flexibility allows for new and better integration between truck and bodywork. This facilitates a much smoother and more cost-efficient bodybuilding process, as well as improving traction, payload and productivity. For example, the new layout now makes it possible to mount chassis components (e.g. fuel tank) starting either from the front- or the rear axle. The improved weight distribution can significantly increase payload potential, while at the same time creating free space for additional chassis components.

Find out more by downloading the Scania Modular Architecture Chassis brochure available in the “Download” section

The powertrain's perfect partner

Smaller, smarter, lighter and more efficient. Alongside Scania Super, a new flexible chassis and tank programme is introduced, making it possible for the truck to reach the same or even greater distances with smaller fuel tanks. Here’s how it all comes together.

When it comes to developing the most energy-efficient truck the transport industry has ever seen, everything counts. Which is why Scania has put considerable resources into developing a new flexible chassis and tank programme, which plays an important part in realising the full potential of the new engine range, aftertreatment system, gearbox and rear axles.

“The new tank programme enables us to maximise the uptake of fuel in the tank. Our philosophy during the development project was: “Why carry extra fuel as dead weight, when you can use it for load capacity instead?” says Aline Ferraz Larsson, a design engineer at Scania R&D.

The new chassis and tank programme features D-shaped fuel tanks made from aluminium. The new tanks are more robust yet also lighter, and their design increases fuel utilisation. New side-mounted SCR tanks are also included. All of this increases the vehicle’s uptime.

At the same time, Scania’s developers have improved the flexibility of the frame and the chassis composition.

“This gives the customer more choice for where to place the tanks on the frame, which is a great improvement for both them and truck body builders, since it creates opportunities for more efficient load distribution,” says Paula Pukk, Scania’s Head of SCR System Installation.

One of the keys enablers of Scania Super’s unmatched efficiency is the clever new fuel optimisation unit. This unit is attached to the primary tank and works as a catch tank.

“The way that the catch tank is set up with electrical pumps enables the user to have ‘fuel on demand’: we get exactly the amount of fuel the engine needs, and no more,” says Alex Elofsson Alenius, a development engineer who worked on the project.

The fuel optimisation unit brings a host of other improvements for customers, and for the overall performance of the powertrain. There are now longer service intervals for the two pressurised fuel filters. These service intervals have been aligned with the oil change intervals, which means fewer visits to the workshop and more time on the road.

Island - 7

Driving the shift

The new Scania Super powertrain – with additional fuel savings of 8 percent compared to our already highly-efficient current engine range – delivers the next chapter in our ambition to drive the shift towards sustainable transport systems.

Science-based targets

Not only is this part of our DNA, but it is also something which we commit to as part of the critical Paris Climate Agreement. In 2020, Scania became the first major manufacturer of heavy commercial vehicles to officially adopt science-based carbon reduction targets. As part of this, we are committed to reducing the total value chain carbon impact not only of our own operations, but of our vehicles while they are in use by our customers – by 20 percent until 2025 (from a 2015 baseline).

Beyond delivering the industry’s leading range of fuel-efficient powertrain solutions, Scania is also committed to delivering other initiatives and services that further reduce carbon emissions, both in combustion-based and electrified vehicles. These include customised driver training to improve energy efficiency, enhancing our vehicle specifications, and creating new models for supplying green electricity and renewable fuels to our customers.

The future really is Super.

Ready for the road ahead

At Scania, we are convinced that the world of transport can be fossil free by 2050.

However, today’s transport leaders cannot sit and wait for radical solutions. There will be no silver bullet. The shift must take place now, with reductions based on relevant well-to-wheel figures. Transport leaders need solutions that can deliver on critical operational and business demands, while still meeting tomorrow’s tough emissions regulations.

For that reason, the internal combustion engine and diesel fuel will continue to be the main pillars of road transport systems for the rest of this decade. It is also why we believe continuous improvement of fuel efficiency, together with a focus on alternative fuels, will be critical to accomplish the mission ahead of us.

That mission continues with the Scania Super, a powertrain that is ready today to meet your operational, business and emissions compliance demands of tomorrow.

Powered by low-emission fuels

The Scania Super is not only the most fuel-efficient engine we have ever built, it’s also fully compatible with low-emission HVO fuels, as well as biodiesel/FAME fuels on the 460- and 500 horsepower range.

Internal combustion engines which run on renewable fuels play a key role in reducing emissions and can provide an immediate solution to meet climate and environmental targets for specific markets. This is especially true for high-mileage, long-distance operations and applications.

Scania has vast experience of powertrains that run on renewable fuels. For three decades we have been the company that has offered the industry’s broadest range of products with the capacity to run on alternative or renewable fuels. The new Scania Super delivers on that commitment.

HVO

Available on the entire Scania Super horsepower range, HVO (hydrogenated vegetable oil) fuels can reduce CO2 emissions by up to 90% compared to standard diesel. HVO can be made from waste oil, rapeseed oil and animal fat, and used to create high-quality, bio-based diesel fuels.

Biodiesel

Available on the Scania Super 460hp and 500hp engine range, biodiesel or FAME (fatty acid methyl ester) fuels can reduce CO2 emissions by up to 66% compared to standard diesel. Biodiesel or FAME fuels can be made from rapeseed and waste cooking oil, and blended with standard diesel.

“A truck that future-proofs my business”

Swedish haulier Daniel Karlsson’s field test of a Scania Super powertrain makes him confident he’s found a truck that blends sustainability with money-saving fuel efficiency for the years ahead.

It’s raining cats and dogs at the yard of Daniel Karlsson Transport in Örebro, mid-Sweden, as a 460 R truck, equipped with the new Super powertrain, waits to be loaded with piece goods such as textiles and bags of garden soil for the regular journey west to Gothenburg. But the weather on this Wednesday in late May is not dampening the enthusiasm for what, so far, has been a highly productive field test.

DK Transport received the truck in December 2020, and since then the vehicle’s new 13-litre engine has been propelling it about 10,000 kilometres per month on this key route in the company’s standing roster of transports around the central belt of Sweden.

Karlsson’s a long-time Scania customer, and the new powertrain’s efficiency and reliability have only strengthened his loyalty.

Nowadays, Karlsson has 17 Scania trucks in his fleet, and 20 drivers. He cites Scania trucks’ reliability and total cost of operation as their most consistent attributes, but one of the reasons he is so happy to be testing the new truck is the powertrain’s sustainability.

”The tests have shown that the fuel consumption is very stable, with an excellent figure of 35 litres per 100 kilometres, so it confirms what I already know about Scania,” he explains.

The field test truck in Daniel Karlsson´s fleet runs on biodiesel.

“Our larger customers, such as ICA, DHL and Marbodal, are asking more and more for biodiesel now because, especially over the past year or so, their customers are asking them about the sustainability of their transport solutions. So now I see that it’s the right move from Scania to progress that development for biodiesel as a stepping stone to electrification,” Karlsson says.

In fact, the 460 R is being driven on biodiesel made from rapeseed oil, which grows in golden abundance in the fields of central Sweden. Daniel Karlsson is no stranger to this fuel. “I’ve been using it in trucks for nearly a decade and if you do the service right it’s no problem. The rapeseed oil has also become a lot better over the years,” he says.

Ultimately, the haulier has a few simple sustainability goals.

“We should be driving on the best available fuel for the environment – biodiesel – and try to only have Euro 6 trucks. Then, of course, when I work with the fuel consumption, that’s another good thing for the environment – because the lower the fuel consumption, the lower the CO2 emissions. We’re future-proofing the business by responding to the demand for sustainability,” says Karlsson.

Island - 8

Performance on a new level

Industry-leading engine performance demands a highly-efficient gearbox. The Scania Opticruise gearbox range, now available in two performance steps G25 and G33, are indispensable to the Super powertrain’s superior fuel economy and set the highest industry standard for gearbox performance.

As a truly integrated part of the overall powertrain management, the new Opticruise’s wider gear ratio spread, together with faster axle gearings, combine to deliver an almost seamless transfer of power across the Super powertrain and enable higher engine torque at lower RPM. As one of the smoothest, efficient and smartest gearbox systems on the market, the Scania Opticruise remains the leading choice for sustainable, fuel-efficient transport operations.

Outstanding efficiency

Through a new variable oil volume and oil spray system, the Scania Opticruise G25CM and G33CM offer improved oil-flow distribution which ensure less internal friction and contribute to reduced internal losses by 50%. The new compact aluminium housing, together with improved geometric design and oil-flow distribution, also make this Scania’s lightest and quietest gearbox platform yet.

More gear options

Based on a wider and more efficient 14-gear ratio, the control system of the Scania Opticruise G25CM and G33CM will automatically select the optimum gear for every driving situation. This is complemented by improved reversing performance, featuring four automated-shift reverse gears as a standard, with the option of eight reverse gears in total.

More control

Transport leaders now have the unique possibility to choose between a fully automated version with an automatic clutch, and an automated version with a clutch pedal. Both offer supreme control, fuel economy and driveability in every situation.

The operational difference

- Faster, smoother gearchanges, giving outstanding comfort and control

- Combines good startability with slow rear axle gear ratio

- Available in 12+2 speed versions, with crawler and overdrive

- Up to 8 reverse gears designed for optimal engine speed regardless of high or low vehicle speed

- Wide ratio spread ranging from a crawler gear, ratio 1:20,8 to an overdrive gear ratio of 1:0,777

- Adaptive shift strategy based on style of driving, load and inclination of the road

- Longer service intervals, resulting in higher uptime and reduced costs

- Oil change intervals are now greatly improved due to higher precision and the addition of larger oil filters and high-quality oil

- The Scania Opticruise G25 and G33 deliver a more powerful, fuel-efficient, low-noise and low-weight clutch-driven power take-off (PTO) range, offering even higher continuous power output to support heavier equipment

| Weight (comp-ared to GRS905) | Engine recomm-endation | Torque capacity |

G25 | 75kg lighter | Up to 460hp | 2500Nm |

G33 | 60kg lighter | Above 460hp | 3300Nm |

Find out more by downloading the Scania Opticruise gearbox brochure available in the “Download” section

The engine's steady sidekick

Scania’s new gearbox is key to realising the fuel-saving potential of the Super engine platform. Light, compact, smooth and quick, it is the perfect match for the new 13-litre engines.

When Scania’s engine developers were pushing the limits to create the cleanest and leanest combustion engine platform the world has ever seen, they had to give it the best possible conditions to fulfil its full potential. That’s why, even at an early stage in the development project, there were tight connections between Scania’s engine developers and their transmission and gearbox colleagues.

“This approach made it possible for us to design the new powertrain totally from scratch, with a holistic perspective,” says Peer Norberg, Senior Engineer in Scania’s transmission development team.

Per Arnelöf, Expert Engineer, Scania gearbox development, adds:

“It was extremely motivating for us to have the initial discussions with the engine technicians and to realise how far you can actually go with an internal combustion engine when it comes to efficiency. From the very start, our focus was not only on designing a cutting-edge gearbox, but to optimise the whole powertrain to meet the customers’ demands.

“Many features of the new G25 gearbox were introduced already with the G33 but what’s great is that we manage to take it a step further; for example, when it comes to reducing internal losses,” says Norberg.

Arnelöf adds: “The new gearbox changes gears in a fantastic way. It’s responsive, quick and smooth. And as we also worked on the sound characteristics, it’s also very quiet; it doesn’t have the predecessor’s hisses and clanging.”

A key feature of Scania’s new gearbox platform is its increased gear ratio spread: 60 percent more than the previous GRS905 model. This makes it possible to optimise the rear axle gear for low engine revs in cruising speed without sacrificing startability. That’s good news for fuel consumption and the climate.

“We make it possible to take further steps towards low engine revs. You can cruise on the highway at 80 km/h on gear 12 and then shift to overdrive in slight downhill conditions, coming down to an amazing 850 revs,” says Arnelöf.

“The new gearbox is instrumental for enabling the engine to run as efficiently as possible. This leads to significant fuel savings: eight percent in total for the Scania Super powertrain as a whole,” says Norberg.

Island - 9

Contact us

Dealer locator

Downloads

Island - 10

Scania Super 13-litre engine

Serving as the heart of a powertrain that sets a new industry standard for fuel efficiency, the new Scania Super 13-litre inline 6-cylinder engine is the most advanced internal combustion engine we have ever built.

Scania Opticruise G25 & G33 Gearbox

As an integral part of the new powertrain’s superior efficiency, the new Scania Opticruise G25 and G33 gearbox range launches as one of the smoothest, smartest and most efficient gearbox systems in the history of transport.

R756 Rear axle

Introducing a wider gear ratio range, the faster-gearing Scania R756 single reduction rear axle not only exceeds in enabling the exceptional fuel efficiency of the new powertrain, but it is also robust enough to master a whole range of haulage applications.

Modular architecture chassis

As our most versatile and robust chassis yet, the new Scania Modular Architecture Chassis not only offers you a more predictable chassis layout, but it also is made to improve the load distribution, payload potential and operative range of your Scania truck.

Legal requirement

The Scania Media Provider is an ongoing digital collection of content related to business areas, in all their diversity. It includes material, images and films for all product areas, pictures of staff, buildings and events, material related to research and development, production, components and historical subjects. Its scope s global. The main focus is on our products after 1995.

All contents of the Scania Media Provider are copyright © Scania CV AB (publ), SE-151 87 Södertälje, Sweden, or its subsidiaries. All rights reserved.

Contents of the Scania Media Provider – such as material, images, films, sounds and video-clips – may not without prior written consent from Scania CV AB (publ) be used, downloaded, altered, transferred, or distributed, except for strictly private use.

Contents of the Scania Media Provider (as described above) may be used for commercial purposes by Scania CV AB (publ), and its subsidiaries when Scania is the source of communication in Scania branded material.

Except as explicitly stated above, Scania Image Desk, imagedesk@scania.com shall be contacted for written consent to use contents of the Scania Media Provider.

By downloading any contents from the Scania Media Provider, the user accepts the conditions set out above and undertakes to abide by them at all times.

Downloads

Images

Brochures